Lost Wax Casting Process Explained: A Step-by-Step Guide from OEM Factories

Ningbo Pingheng Machinery Co., Ltd. specializes in the lost wax casting process, offering high-quality equipment for each stage. The journey begins with our precision wax injection machines, which create detailed wax patterns. These patterns are then assembled onto a central sprue to form a wax tree. The next step involves coating the wax tree with ceramic slurry and allowing it to cure to form the mold. Once the mold is ready, it is heated to eliminate the wax, creating a cavity that mirrors the original pattern. Our comprehensive range of casting equipment, including induction melting furnaces and vacuum casting machines, ensures accurate temperature control and optimal metal flow. This results in exceptional castings with fine details. From wax injection to metal casting, Ningbo Pingheng Machinery Co., Ltd. provides complete solutions tailored to your lost wax casting requirements.

- Investment Cast 316 Stainless Steel Factories

- Investment Cast 316 Stainless Steel Manufacturers

- Investment Cast 316 Stainless Steel Suppliers

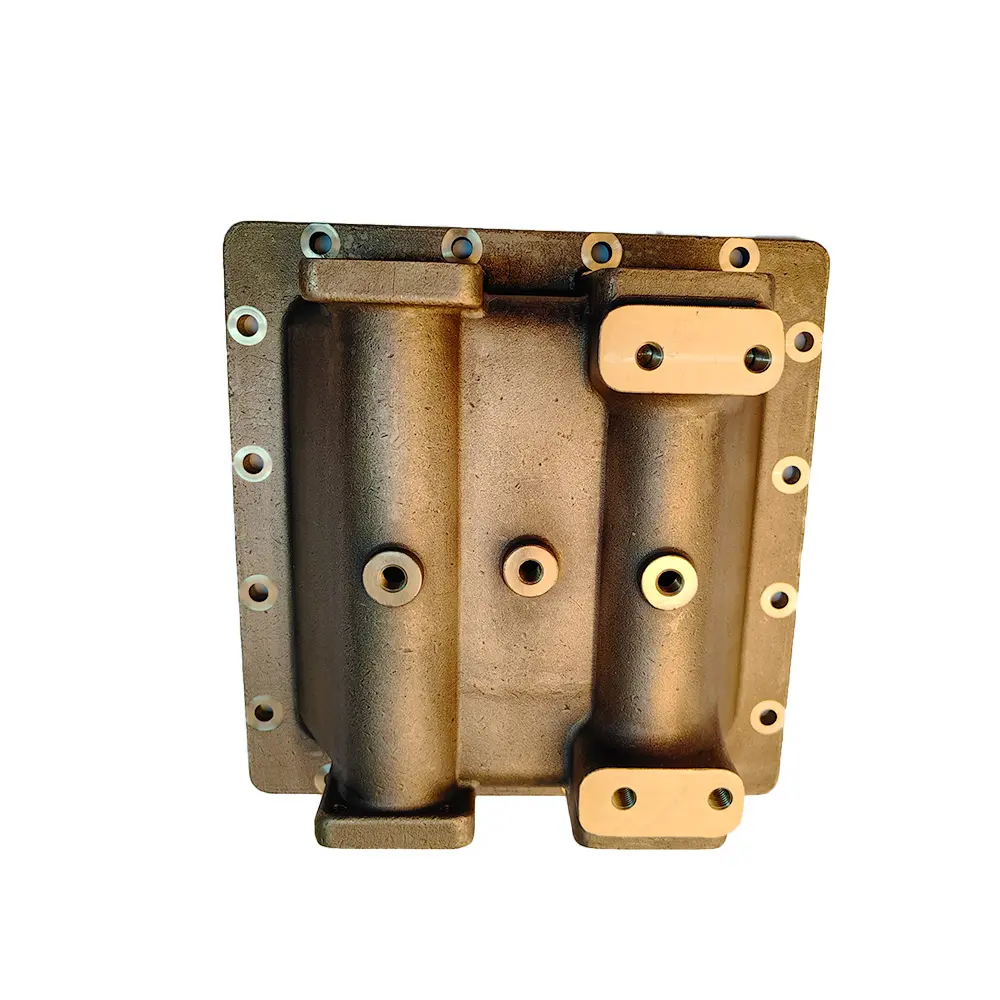

- Copper Investment Casting Supplier

- Copper Investment Casting Manufacturer

- Copper Investment Casting Factory

- Copper Investment Casting Factories

- Copper Investment Casting Manufacturers

- Copper Investment Casting Suppliers

- Alloy Investment Casting Supplier