Precision Casting: Discover C83600's Top Uses

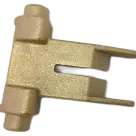

C83600, also known as leaded red brass, stands out for its robust properties. Comprising approximately 85% copper, along with lead, tin, and zinc, this alloy offers moderate strength and excellent corrosion resistance. These characteristics make it ideal for Precision Casting applications. Industries frequently use C83600 in crafting valves, flanges, and marine fittings due to its durability and reliability. Its ability to withstand harsh environments ensures long-lasting performance, making it a preferred choice for components exposed to water and atmospheric conditions.

Exploring the Properties of C83600 Alloy

C83600 alloy, known for its exceptional machinability and corrosion resistance, plays a crucial role in industrial applications. The lead content in this alloy enhances its machinability, allowing for precise manufacturing of components. This makes C83600 an excellent choice for applications requiring durability and precision. Its corrosion resistance ensures longevity, making it suitable for environments where exposure to harsh conditions is common. Industries benefit from C83600 precision casting, which offers cost-effective solutions and efficiency in production processes. Understanding these properties helps industries leverage the alloy's full potential for various applications.

C83600 Precision Casting: How It's Done Right

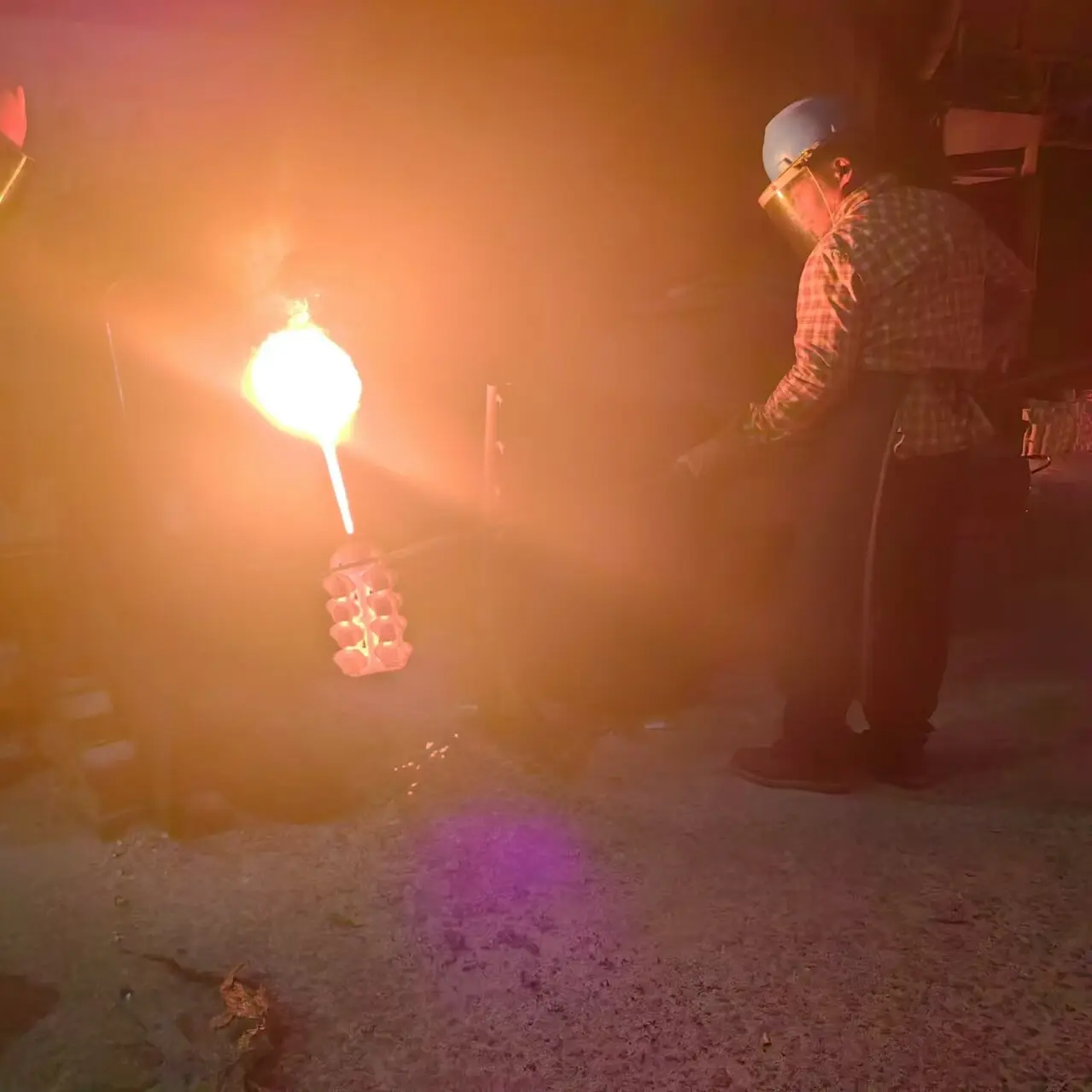

You will find C83600 precision casting to be a fascinating process. This method involves melting the leaded red brass alloy and pouring it into molds to create precise shapes. Precision and quality play crucial roles in this process, ensuring that the final products meet high standards. The steps include preparing the mold, melting the alloy, pouring it, and allowing it to cool and solidify. This technique is widely used in creating components like valves and pipe fittings due to its strength and corrosion resistance. Understanding these steps helps you appreciate the craftsmanship involved.

Exploring the Uses of C83600 in Precision Casting

C83600 precision casting plays a crucial role in modern manufacturing. This alloy, known for its exceptional wear resistance, finds applications in various industries. Its corrosion resistance makes it ideal for environments where durability is paramount. Industries rely on C83600 for components that demand precision and reliability. The alloy's unique properties ensure that castings maintain their integrity over time. Manufacturers choose C83600 for its ability to withstand harsh conditions, ensuring long-lasting performance. Its versatility and robustness make it a preferred choice for precision casting applications across diverse sectors.

C83600 Precision Casting vs. Other Alloys

C83600 precision casting stands out among casting alloys due to its unique composition and properties. This copper-based alloy, also known as Leaded Red Brass, contains approximately 86% copper, 6% lead, 6% tin, and 6% zinc. These elements contribute to its moderate strength, good machinability, and excellent corrosion resistance. Selecting the appropriate alloy for specific applications is crucial. C83600's versatility makes it suitable for a wide range of uses, from architectural fixtures to marine fittings. Understanding these characteristics helps industries make informed decisions, ensuring optimal performance and longevity in their products.

Stainless Steel Casting: How It Powers Machinery

Stainless Steel Casting plays a pivotal role in engineering machinery, offering unmatched strength and resilience. This process enables the creation of complex components that withstand harsh environments, ensuring machinery operates efficiently and reliably. Industries such as automotive, aerospace, and construction heavily rely on stainless steel casting due to its corrosion resistance and durability. The global market for 304 stainless steel casting, valued at approximately $10 billion in 2023, underscores its significance and growing demand. By enhancing performance and extending the lifespan of machinery, stainless steel casting remains indispensable in modern engineering.

How Stainless Steel Casting Boosts Machinery

Stainless steel casting significantly enhances machinery performance and durability. This process offers a high degree of accuracy and the ability to produce parts with complex geometries and intricate details. The mechanical properties of stainless steel make it ideal for applications requiring high strength and long life. Additionally, stainless steel castings yield strong materials with less weight compared to other castings. The Investment Casting method allows for precision components across various industries, ensuring efficient production and reliable repeatability. These superior properties make stainless steel casting a crucial element in engineering machinery.

Crafting Bronze Sculptures from Clay

Bronze sculptures captivate with their timeless elegance and durability. I find the process of transforming clay into bronze fascinating. This journey involves a blend of art and science, where creativity meets precision. Bronze casting, a technique used for centuries, results in sophisticated and valuable pieces. These sculptures often become cherished investments, lasting for generations. The allure of bronze lies in its ability to capture intricate details, making each piece unique. As I delve into this craft, I appreciate the skill and dedication required to create such enduring art.

Bronze Casting: Discover Top Products Today

Bronze casting plays a crucial role in modern applications, offering you a blend of durability and aesthetic appeal. This ancient technique remains relevant today, with its products gaining popularity across various industries. You can find bronze casting in art, architecture, and industrial components, showcasing its versatility. The global bronze market continues to expand, driven by the rising demand for aluminum and phosphor bronze. As you explore these products, you'll discover their diverse uses and the craftsmanship involved in creating them.

How to Cast Bronze Sculptures Step by Step

Bronze casting has been a revered art form for thousands of years, allowing you to transform molten bronze into stunning sculptures. This process involves pouring the liquid metal into a hollow mold, resulting in a beautifully crafted piece. Two primary methods dominate this craft: sand casting and lost-wax casting. Each technique offers unique steps and challenges. Understanding these steps is crucial for achieving successful results. Bronze, known for its versatility and ease of casting, remains the preferred choice for sculptors worldwide. By mastering these techniques, you can create timeless works of art.