How Stainless Steel Investment Castings Enhance Train Durability

Stainless steel Investment Castings play a pivotal role in enhancing train durability. These castings offer exceptional strength and toughness, crucial for withstanding the dynamic loads and wear experienced in rail transport. Their high corrosion resistance ensures longevity even in harsh environmental conditions. The precision of the investment casting process allows for the creation of complex components with excellent surface finishes, meeting stringent industry standards. This combination of durability, precision, and resistance makes stainless steel investment castings an ideal choice for manufacturing reliable train components.

How Stainless Steel Castings Enhance Train Safety

Stainless steel investment castings play a pivotal role in enhancing train safety. These castings provide durable and reliable components essential for maintaining the structural integrity of trains. Stainless steel's properties, such as corrosion resistance and strength, make it an ideal choice for train applications. Its ability to withstand significant impact without fracturing ensures better crashworthiness, reducing injury risks during accidents. Additionally, stainless steel's fire resistance and recyclability support sustainable practices in railway manufacturing. By minimizing deformation in accidents, stainless steel aids in efficient rescue operations, further ensuring passenger safety.

How Stainless Steel Casting Boosts Train Safety

Stainless steel investment casting plays a pivotal role in enhancing train safety. This process creates durable, corrosion-resistant components essential for modern rail systems. Stainless steel, known for its remarkable strength and longevity, significantly outperforms traditional materials like steel or aluminum. Rail cars crafted from stainless steel boast a lifespan exceeding 50 years, ensuring fewer replacements and reduced maintenance costs. Moreover, the adoption of stainless steel in train manufacturing has contributed to a notable decline in train accidents and derailments, underscoring its reliability and effectiveness in safeguarding passengers and crew.

How Stainless Steel Castings Enhance EGR Coolers

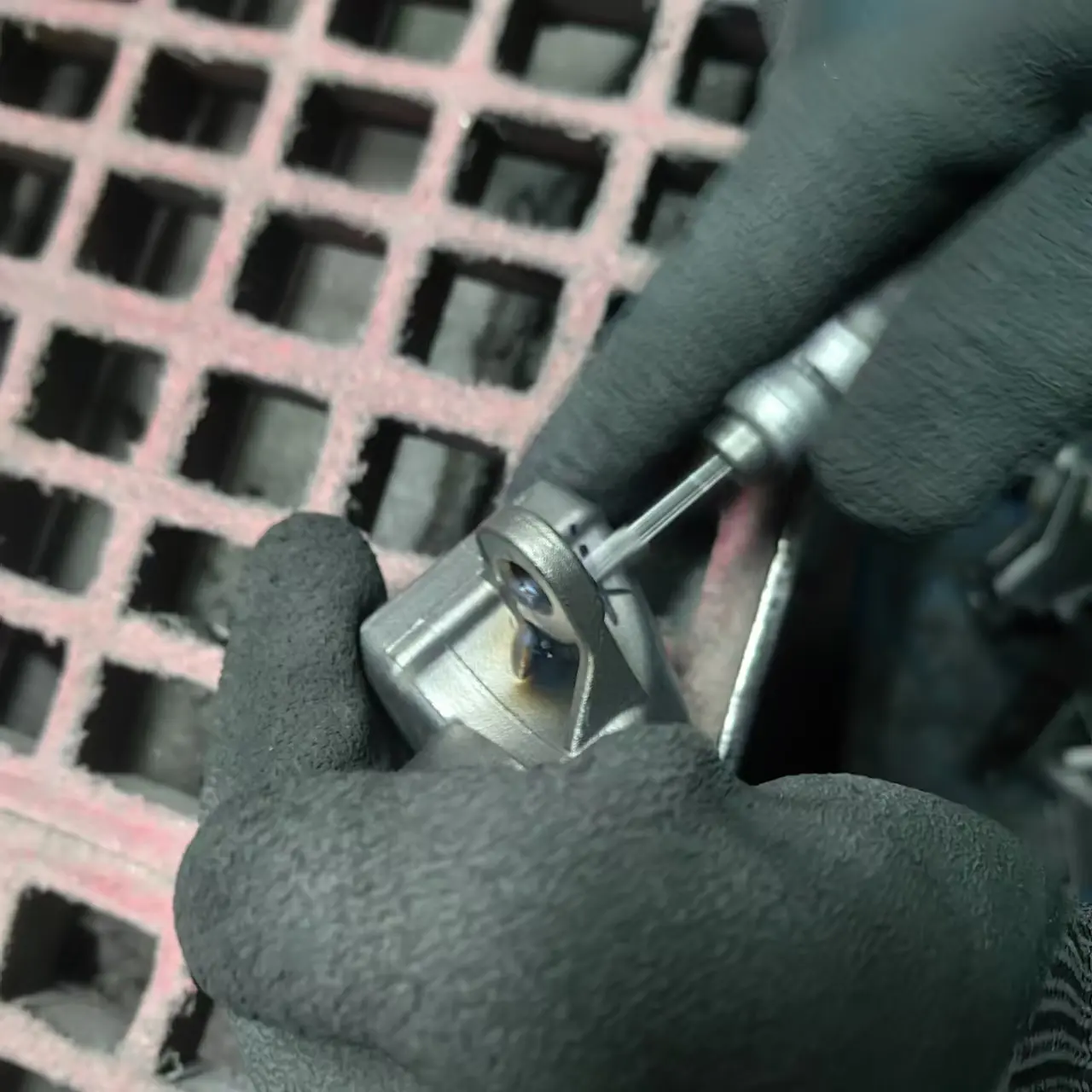

Stainless steel investment castings play a crucial role in enhancing the durability and performance of EGR coolers. These components face harsh conditions, including exposure to corrosive exhaust gases and high temperatures. The choice of material significantly impacts the efficiency and longevity of EGR coolers. Stainless steel, known for its durability and recyclability, offers superior resistance to corrosion and heat. This makes it an ideal choice for automotive applications, where reliability and performance are paramount. By utilizing stainless steel investment castings, manufacturers can ensure that EGR coolers maintain optimal functionality over extended periods.

How Stainless Steel Castings Boost EGR Coolers

Stainless steel investment castings significantly enhance the performance and durability of EGR coolers. These castings offer improved heat resistance, which helps in reducing emissions. Stainless steel stands out as a preferred material due to its excellent corrosion resistance and strength. This makes it ideal for components exposed to harsh environments. Unlike aluminum, which may improve weight and fuel economy, stainless steel provides superior durability and longevity. The precision of investment casting allows for intricate designs, ensuring optimal functionality in automotive systems.

How Stainless Steel Investment Castings Enhance EGR Coolers

Stainless steel investment castings significantly enhance EGR coolers by boosting their performance and durability. These castings offer superior material properties, such as exceptional corrosion resistance and high-temperature tolerance. This makes them ideal for heavy commercial vehicles and emission control systems that demand robustness and longevity. The precision in manufacturing ensures that EGR coolers operate efficiently, contributing to the overall effectiveness of automotive systems. By utilizing stainless steel investment castings, manufacturers can achieve a balance between durability and efficiency, ensuring that vehicles meet stringent emission standards while maintaining optimal performance.

How Stainless Steel Castings Enhance EGR Coolers

Stainless steel investment castings significantly enhance EGR coolers by offering unmatched durability and performance. These castings excel in environments that demand high corrosion resistance and withstand extreme temperatures. Their robust nature ensures that EGR coolers maintain optimal functionality over extended periods. This reliability makes them indispensable in automotive applications where efficiency and longevity are paramount. By integrating stainless Steel Castings, manufacturers achieve superior quality and performance, ensuring that EGR coolers operate effectively under challenging conditions.

How Stainless Steel Investment Castings Enhance EGR Cooler Performance

Stainless steel investment castings significantly enhance EGR cooler performance by improving durability, thermal resistance, and corrosion resistance. These castings withstand high temperatures and pressures, ensuring reliable operation in demanding environments. The choice of materials plays a crucial role in optimizing EGR cooler performance. Stainless steel, known for its excellent mechanical properties, offers a robust solution. Its ability to resist corrosion and maintain structural integrity under thermal stress makes it ideal for automotive applications. By selecting the right materials, manufacturers can achieve superior performance and longevity in EGR coolers.

Precision Casting Applications in Modern Industries

Precision casting stands as a pivotal process in modern industries, offering unparalleled accuracy and efficiency. This technique allows manufacturers to produce intricate components with minimal waste, enhancing both quality and cost-effectiveness. Industries such as aerospace, automotive, and defense heavily rely on precision casting for its ability to create high-strength, lightweight parts. The global precision casting market reflects its growing importance, with projections indicating a rise from USD 14.09 billion to USD 24.52 billion by 2030. This growth underscores the critical role precision casting plays in advancing industrial capabilities.

What Are the Applications of Precision Casting?

Precision casting plays a crucial role in manufacturing intricate and high-quality metal components for various industries. This process ensures the production of parts with exceptional accuracy and detail. Industries such as medical, aerospace, automotive, energy, military, and food and beverage rely heavily on precision casting.