Why Silicone Sol Investment Casting Stands Out

Silicone sol Investment Casting offers unique benefits that set it apart from other casting methods. You will appreciate its precision, which ensures high dimensional accuracy in every casting. The process also delivers an exceptional surface finish, reducing the need for additional machining. Its versatility allows you to cast a wide range of metals, making it suitable for various applications. Industries increasingly favor this method due to its ability to produce intricate designs and thin-walled castings. As you explore its advantages, you'll understand why silicone sol investment casting continues to gain popularity.

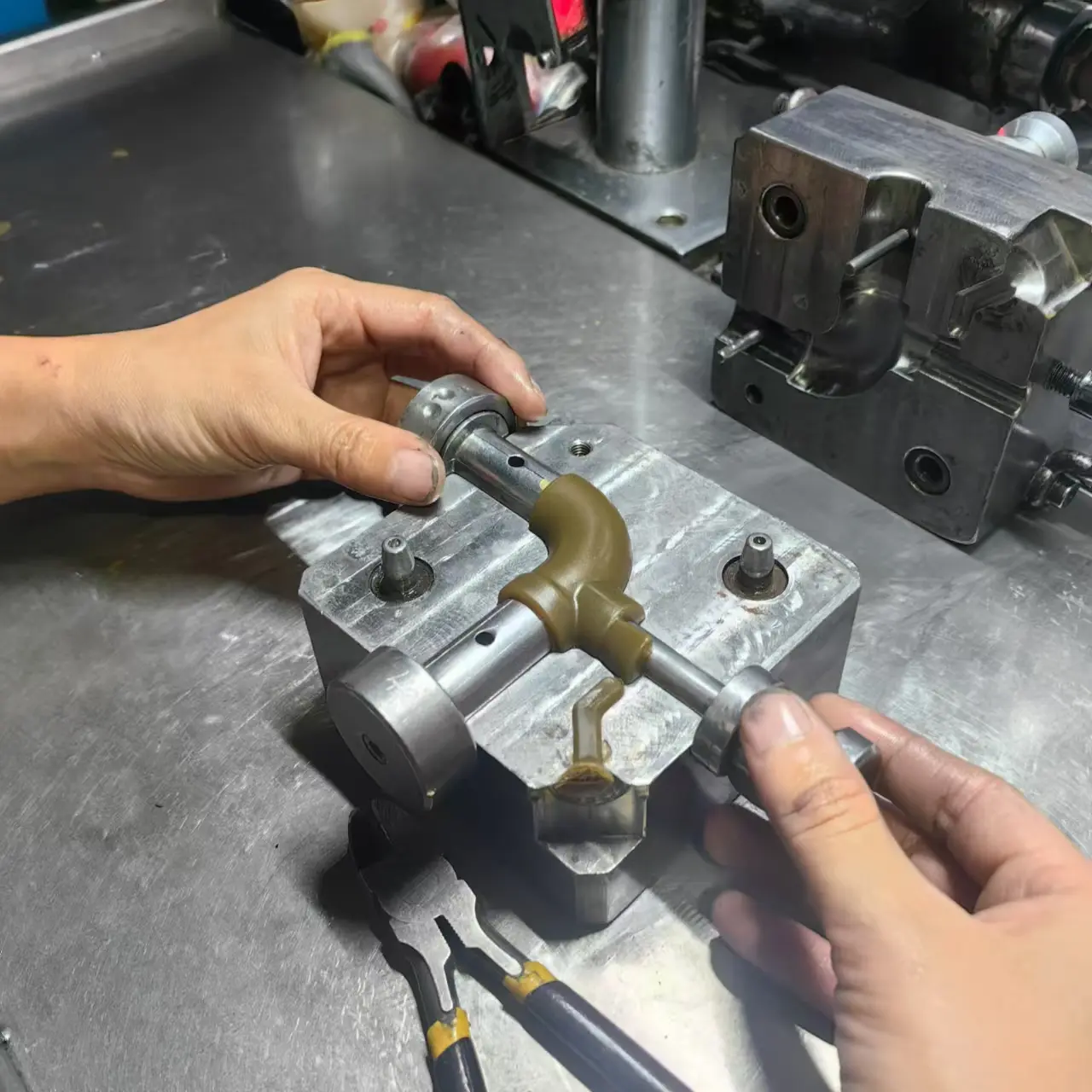

Tracing the History of Silicone Sol Investment Casting

Silicone sol investment casting stands as a pivotal process in modern manufacturing. This technique uses a silica-based solution to create intricate and high-Quality Castings. Manufacturers rely on it to produce complex and precise components with remarkable accuracy. The method's ability to achieve detailed geometries makes it indispensable in industries requiring high precision. Its significance lies in enhancing the mechanical properties of cast products, offering superior surface finishes and dimensional accuracy. As a result, silicone sol investment casting has become a preferred choice for producing components that demand exact specifications.

Exploring the Benefits of Silicone Sol Investment Casting

Silicone sol investment casting offers you several advantages. You achieve high precision, ensuring tight tolerances in your components. This method provides a superior surface finish, reducing the need for additional machining. You benefit from material versatility, allowing the use of various metals and alloys. Cost-effectiveness stands out as a key advantage, making it suitable for both small and large production batches. These benefits play a crucial role across industries, enhancing product quality and efficiency.

Why Silicone Sol Investment Casting is Ideal

Silicone sol investment casting offers you unparalleled precision and a high-quality surface finish. This method excels in producing components with tight tolerances and exact geometry, ensuring superior surface quality. You can choose from a wide range of metals and alloys, making it versatile for various applications. The process is efficient, reducing waste and material usage. Industries benefit from its cost-effectiveness and reliability, as it minimizes defects and enhances product durability. By opting for silicone sol investment casting, you ensure high precision and smooth surfaces in your components.

Silicone Sol Precision Casting vs Sand Casting

When choosing a casting method, you often weigh precision, cost, and application. Silicone sol Precision Casting excels in producing intricate parts with high dimensional accuracy and smooth surface finishes. This method reduces machining work, saving costs in production. In contrast, sand casting offers a more economical option but with lower precision and rougher finishes. Sand casting may require additional machining to meet specifications. Each method has unique benefits and limitations, making them suitable for different applications. Understanding these differences helps you select the best approach for your needs.

Silicone Sol Precision Casting vs Traditional Methods

Silicone sol precision casting offers a modern approach to creating intricate and detailed parts. You might wonder how it stacks up against traditional casting methods. Understanding these differences is crucial for making informed decisions. Silicone sol precision casting provides superior dimensional accuracy and surface finish, which can be vital for specific applications. By comparing it with traditional methods, you can determine the best fit for your project needs, ensuring optimal results and efficiency.

Exploring the Versatility of Silicone Sol Precision Casting

Silicone sol precision casting represents a transformative process in modern manufacturing. It involves creating high-quality casting shells that ensure superior product quality and yield. This method stands out due to its ability to produce intricate designs with remarkable dimensional accuracy. Industries such as automotive, aerospace, and medical rely heavily on this technique. They benefit from its precision in crafting engine components, turbine blades, and surgical instruments. The versatility of silicone sol precision casting makes it indispensable for applications demanding high performance and reliability.

Why Silicone Sol Precision Casting is the Best Choice

Silicone sol precision casting stands out for its exceptional quality and precision. You benefit from its superior binding properties and high purity, which ensure optimal particle size and stability. This method significantly reduces material wastage and energy consumption, making it an eco-friendly choice. Industries that demand high-quality metal parts find silicone sol precision casting ideal due to its ability to produce intricate designs with precise dimensions and smooth surface finishes. By choosing this method, you contribute to sustainable manufacturing while achieving outstanding results.

Why Choose Medium Temperature Wax for Precision Casting

Why should you consider medium temperature wax for precision casting? This type of wax offers a perfect balance between melting characteristics and dimensional stability, making it a top choice for high-precision applications. You’ll find that medium temperature wax precision casting enhances the quality of your castings by reducing shrinkage rates, which helps maintain the accuracy of the final product. Plus, it’s cost-effective. By minimizing mold repair costs and size fluctuations, you save money in the long run. With medium temperature wax, you achieve superior casting results without breaking the bank.

Complete Guide to Medium Temperature Wax Precision Casting

Medium temperature wax precision casting stands as a pivotal technique in modern manufacturing. You create intricate metal components with remarkable accuracy using this method. The process involves crafting a wax pattern, which is then enveloped in a ceramic shell to form a mold. This technique ensures high dimensional accuracy, crucial for producing complex shapes. The consistency in size and shape of the castings significantly improves due to controlled factors like mold material shrinkage and alloy shrinkage rates. By mastering this process, you can achieve superior quality in metal component production.