In the ever-evolving landscape of manufacturing, "Egr Ss Precision Casting" stands out as a pivotal technique for achieving enhanced performance in industrial applications. As we approach 2025, the demand for precise and efficient casting methods has never been greater, making it imperative to explore the top techniques that will shape the industry in the coming years. Dr. Emily Carter, an esteemed expert in precision casting and materials engineering, emphasizes the significance of innovation in this field, stating, "The future of Egr Ss Precision Casting lies in our capacity to integrate advanced technologies that optimize performance and efficiency."

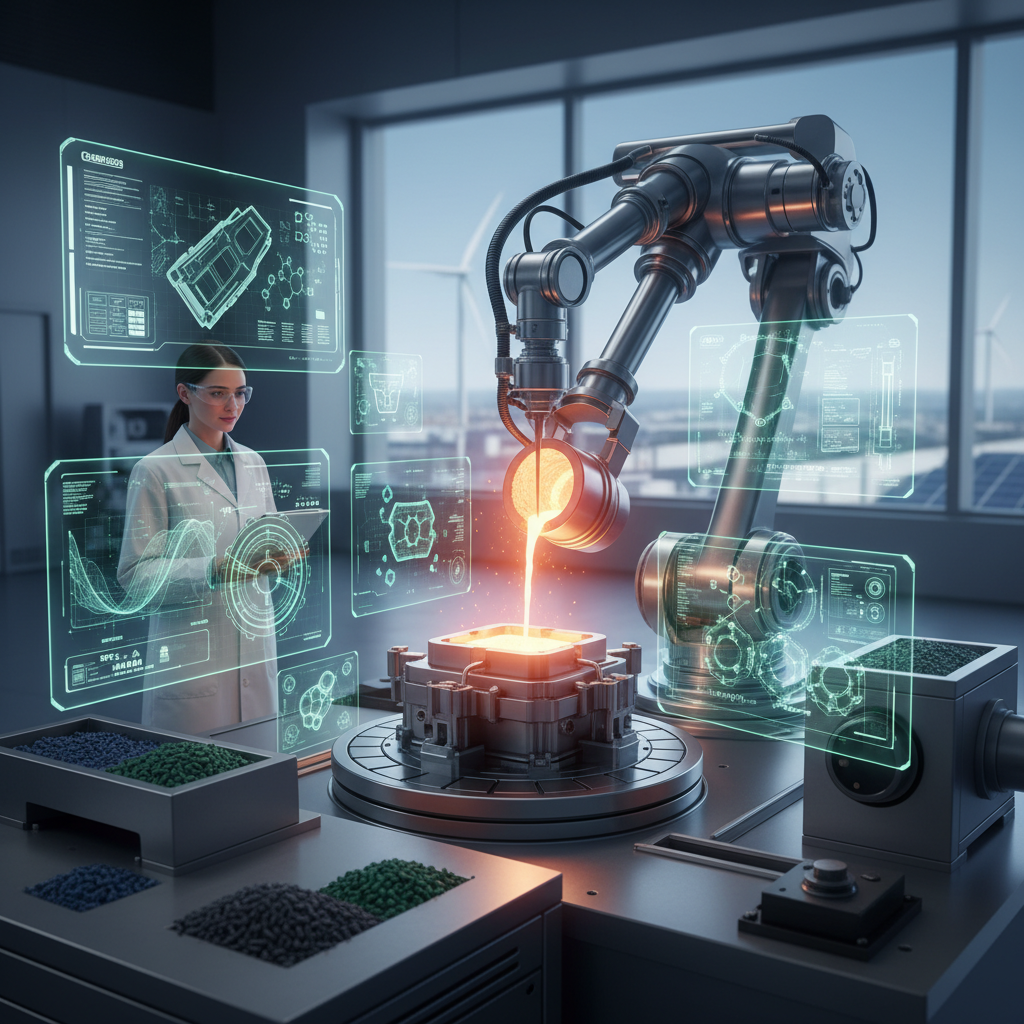

As companies strive to maintain competitive advantages, understanding the intricacies of precision casting techniques becomes crucial. The integration of modern technologies such as 3D printing, AI-driven design, and eco-friendly materials can significantly influence the quality and functionality of cast components. By delving into the top ten Egr Ss Precision Casting techniques expected to dominate in 2025, professionals can gain insights into how to leverage these advancements effectively.

Ultimately, mastering these cutting-edge methods will not only enhance product reliability but also contribute to sustainability efforts within the industry. As we embark on this exploration, it is essential for manufacturers to adapt and innovate to thrive in an increasingly demanding market. The following sections will outline the techniques that promise to revolutionize Egr Ss Precision Casting, setting the stage for a future where precision and performance coexist harmoniously.

The evolution of Exhaust Gas Recirculation (EGR) systems has significantly influenced the performance and efficiency of modern engines. Precision casting techniques have emerged as critical components in this evolution, providing enhanced durability and performance. According to a recent report by the Global Semiconductor Alliance, the automotive industry has seen a 20% increase in demand for EGR systems, driven by stringent emissions regulations and the push for improved fuel economy. These trends highlight the necessity for innovative casting techniques that can withstand the harsh environments typical in EGR applications.

Advanced precision casting methods, such as investment casting and lost foam casting, are now playing an integral role in the production of EGR components. Research from the Society of Automotive Engineers indicates that using these techniques can result in a 30% reduction in manufacturing waste and a corresponding decrease in production costs. Moreover, the improved dimensional accuracy and surface finish achieved through precision casting directly enhance the operational efficiency of EGR systems, leading to better engine performance and lower emissions. These advancements underline the impact of innovative manufacturing methods in meeting the rising standards of performance and sustainability in the automotive industry.

In 2025, the performance of Exhaust Gas Recirculation (EGR) systems relies heavily on the materials used in precision casting techniques. The selection of alloys is critical as they must withstand extreme temperatures and corrosive environments. Recent industry reports indicate that advanced materials like aluminum-silicon alloys are becoming increasingly popular due to their excellent thermal conductivity and oxidation resistance. According to a study by the Automotive Materials Association, 70% of manufacturers are shifting towards using high-silicon aluminum alloys for enhanced durability and weight reduction in EGR components.

Furthermore, the trend towards utilizing tailored cast iron, particularly ductile iron, offers superior strength and wear resistance. A 2023 survey from the International Journal of Advanced Manufacturing Technology found that components made from modern ductile iron show a 30% increase in lifespan compared to traditional materials. Incorporating these cutting-edge materials not only improves the efficiency of EGR systems but also aligns with the industry's focus on sustainability, as better-performing alloys can reduce emissions and increase fuel efficiency by up to 15%. The integration of these technologies is vital for automotive manufacturers aiming to meet the stringent regulations expected in the coming years.

The advancements in casting technologies are revolutionizing the production efficiency and precision of EGR (Exhaust Gas Recirculation) components. With the steel casting market projected to reach USD 42.18 billion by 2029, it is evident that industries are shifting their focus toward high-performance casting techniques. Technologies that enhance the accuracy in the casting process not only reduce material waste but also optimize production timelines. For instance, the aluminum die casting market, valued at USD 85.49 billion in 2025, is expected to grow considerably, highlighting the need for innovative methods that cater to rising demands.

To maximize efficiency, companies should consider integrating quantitative casting furnace technologies, which are expected to reach USD 124.9 million by 2035, showcasing a steady growth trajectory. This integration allows for consistent quality and minimized energy consumption during the casting process.

Tip: Invest in advanced casting machinery and technologies that focus on precision to stay competitive. Utilizing modern techniques can significantly reduce production costs and improve product quality, ultimately boosting your market standing. Adopting sustainable practices will also appeal to environmentally conscious consumers and investors alike.

In the rapidly evolving field of precision casting, rigorous quality control measures are essential to ensure optimal performance and reliability of EGR SS components. According to a recent report by the Casting Industry Association, approximately 30% of casting defects can be traced back to inadequate quality control practices during the manufacturing process. By implementing comprehensive testing protocols, manufacturers can significantly reduce this percentage, leading to enhanced operational efficiency and end-user satisfaction.

One effective approach to quality control involves the integration of advanced non-destructive testing (NDT) techniques. Data from a 2022 study revealed that facilities employing NDT methods, such as ultrasonic testing and radiographic inspection, experienced a 20% decrease in product recalls linked to casting failures. This highlights the crucial role of rigorous testing in identifying potential issues early in the production cycle. Furthermore, regular audits and adherence to industry standards like ISO 9001 contribute to consistent quality assurance, ensuring that each component meets the stringent performance requirements expected in modern applications.

The pursuit of sustainability in precision casting has become paramount as the manufacturing industry faces increasing environmental challenges. Eco-friendly practices are reshaping EGR (Exhaust Gas Recirculation) manufacturing solutions, emphasizing the importance of reducing waste and minimizing carbon footprints. Techniques such as utilizing recycled materials and incorporating bio-based binders not only enhance performance but also align with global sustainability goals. By harnessing advancements in technology, manufacturers can now implement innovative processes that lower energy consumption while maintaining the integrity and precision of cast components.

Moreover, adopting water-based and low-emission coatings can significantly mitigate the harmful effects of traditional casting materials. By prioritizing the use of advanced materials and adopting a life-cycle perspective, manufacturers can facilitate a more circular economy within the precision casting sector. These eco-friendly practices not only contribute to a healthier planet but also improve the overall efficiency and cost-effectiveness of EGR manufacturing solutions, aligning profitability with environmental responsibility. Embracing these sustainable initiatives is essential for the future of the industry, ensuring that it meets the demands of both consumers and regulatory standards while fostering innovation.