Silica Sol Precision Casting has gained significant attention in the manufacturing sector. According to a recent industry report by Market Research Future, the precision casting market is projected to reach $25 billion by 2025. This growth reflects a rising demand for high-quality, intricate components across various industries, including aerospace and automotive. Silica sol casting provides a solution that meets these demands due to its excellent dimensional accuracy and fine surface finish.

Using Silica Sol Precision Casting not only enhances product quality but also optimizes production efficiency. However, achieving the best results requires a deep understanding of the process and its parameters. For instance, the control of pouring temperature and mold preparation can drastically impact the final product’s metallurgical properties. Yet, challenges persist. Companies may face issues related to mold defects and inconsistent results, necessitating careful attention during each casting phase.

In such a dynamic landscape, businesses aiming for success must continuously assess their Silica Sol Precision Casting techniques. Regular audits and updates to the casting process can reveal areas for improvement. There is no one-size-fits-all solution, and flexibility is crucial. Therefore, organizations must remain adaptable while striving for excellence in precision casting.

Silica sol precision casting is a remarkable technology for producing intricate metal parts. This method uses a colloidal silica solution as a binder. The resulting molds provide high precision and excellent surface finish. Industries such as aerospace, automotive, and medical rely on this casting process for its accuracy. Parts created through silica sol casting exhibit fine details that traditional methods struggle to achieve.

The applications are vast. From turbine blades to complex automotive components, the possibilities are endless. Yet, precision casting is not without its challenges. Factors like temperature control and drying time are crucial. Too quick drying can lead to cracks or defects in molds. Skilled technicians are essential to monitor these variables finely.

Experimentation can yield different results. Each casting is a unique piece of art. It often requires several iterations to perfect. There might even be unexpected outcomes that lead to innovation. This process continuously teaches practitioners to adapt and improve. Understanding the nuances of silica sol precision casting can unlock new potential.

| Application | Material Used | Advantages | Best Practices |

|---|---|---|---|

| Aerospace Components | High-temperature alloys | Precision, durability | Use proper coating and maintain temperatures |

| Medical Devices | Titanium alloys | Biocompatibility, precision | Ensure high cleanliness and precision |

| Automotive Parts | Aluminum alloys | Lightweight, high strength | Optimize mold design and cooling systems |

| Industrial Equipment | Steel alloys | High wear resistance | Properly control cooling rates |

| Art and Sculptures | Copper alloys | Aesthetics, detail | Focus on design and finishing |

Silica sol plays a crucial role in precision casting. Its unique properties enhance mold strength and detail accuracy. This results in higher-quality castings that meet tight tolerances. Silica sol also offers excellent surface finishes, reducing the need for extensive machining.

Another benefit is the thermal stability of silica sol. It withstands high temperatures, making it suitable for complex alloys. This flexibility allows for tailored solutions in casting applications.

However, achieving the optimal mix of silica sol and other materials can be challenging. It requires careful testing and adjustments.

Some may find that the cost of silica sol is higher than alternatives. This investment can lead to superior results, though. Manufacturers might struggle initially with the process. Nonetheless, refining the technique can yield significant benefits in the long run.

The journey of using silica sol for precision casting is a continuous learning experience.

Silica sol precision casting is an intricate process that requires careful attention to detail. This method is known for producing high-quality metal parts with excellent dimensional accuracy. The step-by-step approach to silica sol precision casting begins with preparing a wax pattern. The pattern should be free from imperfections. Even small defects can cause problems later.

Next, a coating of silica sol is applied to the pattern. This forms a thin, smooth layer that enhances the final product's surface. It is crucial to allow sufficient drying time between coats. Two to three layers may be necessary for the best results. Don’t rush this part. Patience pays off.

Once the coating is complete, it’s time to invest the pattern in a solid material. This can be a mixture of sand and resin. Ensure the mixture is well combined. If not, the mold may crack during the pouring process. Pour the molten metal carefully to avoid splashes. Monitor the temperature closely to maintain consistent results.

Tips: Check your patterns for tiny bubbles before coating. They can lead to surface flaws. After the mold has set, inspect it for any inconsistencies. This will help ensure your final casting is as flawless as possible. Small oversights can lead to bigger issues later. Take your time and focus on each step.

Silica sol precision casting can present various challenges, especially during the initial phases of the process. One common issue is the formation of defects in molds. These defects often arise from improper mixing and inadequate curing times. Inspecting the mixture consistency is crucial. In some cases, a sticky or too-thick blend leads to uneven surfaces or air pockets.

Another challenge involves temperature control during casting. Too much heat can cause the sol to expand excessively. Conversely, low temperatures may slow down the hardening process, leading to misalignments. Thermocouples can help monitor temperatures effectively. Adjusting the furnace settings can facilitate a more even distribution of heat, ultimately improving the casting quality.

Finally, some may struggle with stripping molds from finished products. This might occur if the mold material is too rigid or if the release agent is inadequate. Experimenting with different mold release agents can yield better results. Reflection on these complications often leads to better practices and improved finished products in silica sol casting.

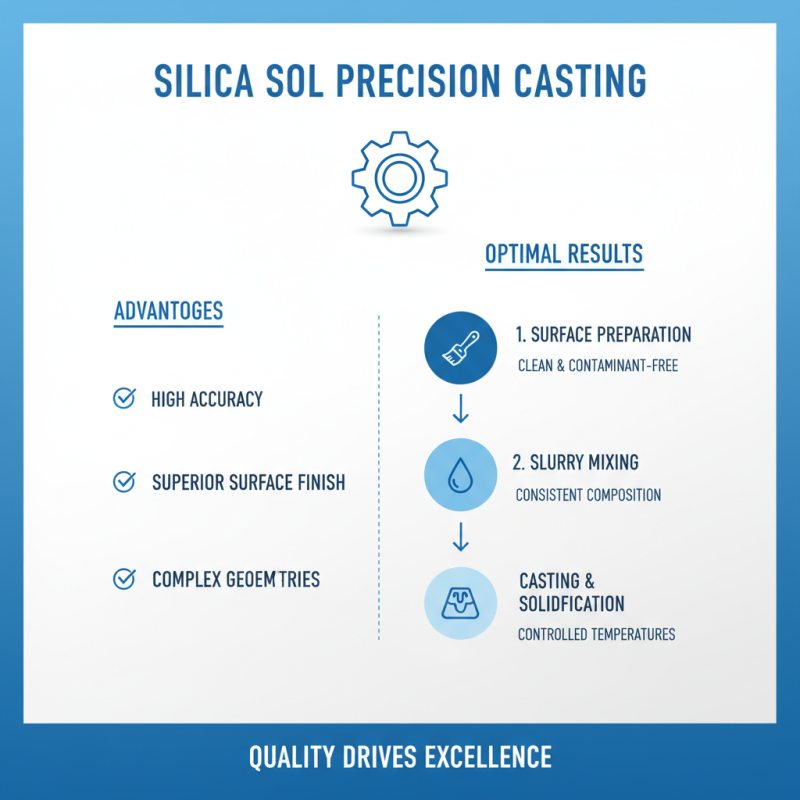

Silica sol precision casting offers numerous advantages. To achieve optimal results, attention to detail is essential. Start with proper surface preparation. Ensure all surfaces are clean and free from contaminants. Any residue can compromise the casting process. This step is often overlooked, yet it significantly impacts the final product.

Temperature control is another critical factor. The silica sol should be maintained at specific temperatures. This ensures that the mold sets correctly. Deviating from the recommended range can lead to defects. Additionally, the timing of pouring is essential. Wait for the right moment when the silica sol is ready. Rushing this step can result in uneven casting.

It's also important to inspect the mold after each use. Small cracks or imperfections can develop over time. Ignoring these issues may lead to larger problems in future casts. Regular maintenance and reflection on past projects can enhance overall results. Every casting project provides lessons. Take note of what worked well and what didn’t. Adjusting your methods based on these reflections can lead to significant improvements.