Silica Sol Casting has emerged as a pivotal technique in the foundry industry, gaining prominence due to its exceptional precision and quality in producing castings. As the demand for high-performance components continues to rise, particularly in sectors such as aerospace, automotive, and medical devices, the benefits of Silica Sol Casting have become increasingly evident. According to a recent industry report by MarketsandMarkets, the global foundry market is projected to reach USD 151.2 billion by 2027, with advanced casting techniques like Silica Sol leading the way in ensuring detailed and intricate designs are achieved.

The innovative properties of Silica Sol Casting allow for tighter tolerances and smoother surface finishes compared to traditional methods. This is largely attributed to the unique binder system used, which enhances mold strength and minimizes dimensional changes during the casting process. Furthermore, the technique excels in producing complex geometries, which is crucial as various industries shift toward lighter and more efficient designs. A study by the International Journal of Engineering Research & Technology indicates that Silica Sol castings can enhance product lifecycle while reducing material waste, underscoring its relevance in contemporary manufacturing practices.

In exploring the ten best Silica Sol Casting techniques, we uncover the strategies that not only optimize precision but also elevate the quality of castings, ensuring manufacturers can meet the evolving specifications of modern design challenges. As industries continue to innovate, the adoption of Silica Sol Casting techniques will play a critical role in shaping the future of precision manufacturing.

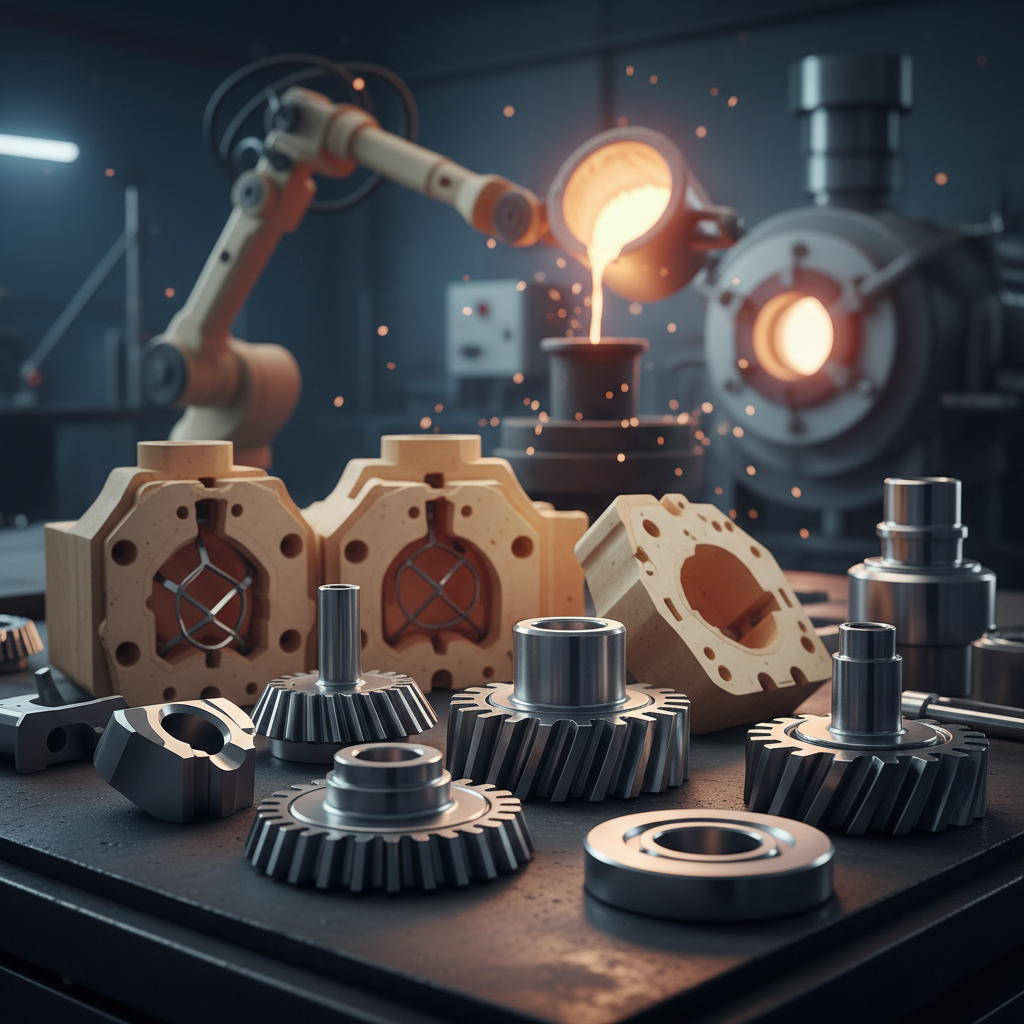

Silica sol casting is a sophisticated method widely used in metalworking, distinguished by its ability to produce components with exceptional precision and surface finish. Central to this technique is the use of a silica sol, a colloidal suspension of silica particles in water, which offers several advantages over traditional casting methods. One primary principle is that the silica sol provides a thin, consistent layer that coats the mold, ensuring that even intricate designs are captured with remarkable detail. This facilitates the creation of complex geometries that would be challenging to achieve through other casting processes.

Moreover, silica sol casting enhances the bonding between the mold and the metal during the pouring process, resulting in minimized defects such as porosity or misalignment. The key to its superior quality lies in its lower thermal expansion coefficient, which contributes to tighter tolerances and better overall dimensional accuracy. Additionally, the process allows for faster production cycles and reduced need for secondary finishing processes, making it economically advantageous. Overall, understanding these key principles not only highlights the effectiveness of silica sol casting but also underscores its growing popularity in industries demanding high-quality, precise components.

| Technique | Key Principles | Advantages | Typical Applications |

|---|---|---|---|

| Lost-Wax Casting | Uses a wax model which is melted away | High dimensional accuracy and fine detail | Jewelry, art, precision tools |

| Shell Molding | Thin shell created from sand and resin | Excellent surface finish and dimensions | Automotive components, castings |

| Investment Casting | Involves creating a ceramic mold | Complex shapes, low waste material | Aerospace, medical devices |

| 3D Printing Casting | Utilizes 3D printing to create molds | Rapid prototyping and customization | Prototype development, low volume production |

| Vacuum Casting | Uses vacuum pressure to fill molds | Detailed reproduction, less air bubbles | Prototype parts, small batches |

| Lost Foam Casting | Uses foam patterns instead of metal | Minimal draft angles, surface finish | Automotive, machinery parts |

| Cold Box Casting | A cold curing system using gaseous hardeners | Good dimensional accuracy and surface finish | Heavy machinery, industrial parts |

| Squeeze Casting | Combines casting and forging processes | High strength and density in components | Aerospace, automotive parts |

| Sand Casting | Utilizes sand to form molds | Cost-effective for large components | Pipes, engine blocks, art sculptures |

Silica sol casting has emerged as a leading technique in manufacturing components that demand high precision and quality. This method utilizes a colloidal solution of silica to create a thin shell mold that provides an exceptional surface finish. Recent industry reports indicate that the use of silica sol casting can reduce dimensional tolerances to as low as ±0.1 mm, making it a favored choice in sectors such as aerospace and automotive manufacturing.

For those seeking to enhance the precision of their silica sol casting processes, one effective tip is to control the ambient temperature and humidity during the curing phase. A consistent environment helps prevent defects and ensures the uniformity of the mold. Additionally, selecting high-quality silica sol can significantly influence the casting’s final properties. According to a study by the American Foundry Society, molds made with premium silica sol demonstrate a 30% improvement in tensile strength compared to standard alternatives.

Finally, incorporating advanced inspection methods throughout the casting process can further elevate quality assurance. Techniques such as laser scanning and X-ray computed tomography allow for real-time monitoring of mold integrity and dimensional accuracy. By leveraging these technologies, manufacturers can ensure that their silica sol cast components meet rigorous industry standards.

The quality of silica sol castings is significantly influenced by several key factors, which determine both the precision and the overall integrity of the final product. One of the primary elements is the viscosity of the silica sol itself. According to a report from the American Foundry Society, optimal viscosity ensures a uniform coating around the pattern, preventing defects such as inclusions and voids. When the viscosity is too low, it can lead to issues such as sagging; conversely, excessive viscosity may result in inadequate filling of the mold.

Another crucial factor is the drying time and temperature during the shell building process. Research indicates that controlling these parameters can reduce the risk of cracking and ensure proper hardening, ultimately affecting the dimensional accuracy of the casting. A study published in the Journal of Materials Science found that variations in drying conditions could alter the microstructure of the shell, impacting strength and thermal resistance properties. Therefore, attention to these details can significantly enhance the performance and durability of silica sol castings, making them a preferred choice in industries where precision is paramount.

Silica sol casting is renowned for its ability to create intricate designs with exceptional precision. However, this technique does present some common challenges that must be addressed to ensure flawless results. One such issue is the risk of defects in the final product, which often arises from inadequate mixing of the silica sol and other materials. This can lead to uneven curing and compromised structural integrity.

To mitigate this, it’s crucial to maintain consistent mixing ratios and thoroughly blend the components. Additionally, controlling the temperature and humidity levels during the curing process can prevent unwanted reactions that may lead to defects.

Another prevalent challenge is air entrapment, which can hinder the casting process and result in imperfections. Using vacuum systems or pressure casting techniques can help eliminate air bubbles before the material sets.

**Tip:** Always perform a trial run with a smaller batch to identify potential issues before scaling up the production process.

Monitoring the viscosity of the silica sol mixture is vital as well. A proper balance ensures better flowability and reduces the likelihood of clogs in intricate molds.

**Tip:** Invest in high-quality mixing equipment to achieve optimal viscosity consistently, ultimately enhancing the quality of your casted pieces.

Silica sol casting has emerged as a revolutionary technique in various modern industries, allowing for the production of intricate components with unmatched precision and surface quality. This method utilizes a colloidal silica solution as a binder, enabling the formation of complex geometries that traditional casting can struggle to achieve. Industries such as aerospace, automotive, and medical manufacturing increasingly adopt silica sol casting for its ability to create lightweight yet durable parts. The low thermal expansion coefficient of silica sol also contributes to enhanced dimensional stability during the casting process.

Furthermore, silica sol casting opens doors to innovative applications. In the realm of aerospace, components such as turbine blades benefit from the method's capacity to handle high thermal applications while maintaining structural integrity. In the medical field, custom implants crafted through silica sol casting offer solutions tailored to individual patient needs, combining precision with biocompatibility. As industries continue to push the boundaries of design and performance, the role of silica sol casting is poised to expand, fostering advancements not only in manufacturing techniques but also in the functionality of end products.