Marine Copper Casting is an innovative and versatile process that has gained significant attention in various industries, particularly in marine applications. This casting technique utilizes copper and its alloys, which are known for their exceptional properties such as corrosion resistance, strength, and excellent thermal conductivity. As marine environments can be particularly harsh, the use of Marine Copper Casting helps to produce components that withstand the challenges posed by saltwater and other elements.

The benefits of Marine Copper Casting extend beyond just durability; it also allows for intricate designs and precise engineering, making it an ideal choice for manufacturing items ranging from marine hardware to complex components used in shipbuilding and repair. Furthermore, the casting process can be tailored to meet specific requirements, ensuring that the final product aligns with industry standards and customer expectations.

In this article, we will explore the various applications of Marine Copper Casting, highlighting its critical role in advancing marine technology. Additionally, we will delve into best practices that can optimize the casting process, ensuring both efficiency and quality in production. Whether you are a manufacturer seeking to understand the advantages of this technique or an engineer looking for reliable solutions in marine applications, this overview will provide valuable insights into Marine Copper Casting.

Marine copper casting is a specialized process used to create components for the maritime industry, focusing on the production of corrosion-resistant parts that are essential for marine applications. This method utilizes copper alloys, renowned for their excellent mechanical properties and resistance to saltwater corrosion, making them ideal for environments where exposure to harsh conditions is inevitable. According to a report from the International Copper Association, copper, and its alloys have demonstrated a long service life, outperforming other materials in marine applications by up to three times, depending on environmental conditions.

The applications of marine copper casting are extensive, ranging from shipbuilding to the manufacturing of various marine components such as pumps, valves, and propellers. These parts often require high durability and reliability, which marine copper casting is well-equipped to deliver. A study by the Marine Technology Society highlights that the use of copper alloys in marine environments can reduce maintenance costs by as much as 40%, providing a significant economic advantage. Moreover, the casting process allows for intricate designs that can enhance performance while minimizing weight, a crucial factor for improving fuel efficiency in marine vessels.

Marine copper casting offers several benefits that make it an essential process in various marine and industrial applications. One of the primary advantages is its excellent corrosion resistance, particularly in saltwater environments. Copper and its alloys possess inherent anti-fouling properties, which help to minimize the growth of marine organisms on surfaces, reducing maintenance costs and enhancing the lifespan of components. This characteristic makes marine copper casting particularly valuable for shipbuilding, underwater infrastructure, and other maritime industries where durability and longevity are crucial.

In addition to corrosion resistance, marine copper casting is known for its superior mechanical properties. The material exhibits high strength and excellent thermal and electrical conductivity, making it ideal for applications requiring robust performance under extreme conditions. This is particularly relevant in the manufacturing of components such as propellers, fittings, and valves, where both structural integrity and functionality are essential. Furthermore,. the versatility of copper alloys allows for the customization of properties to suit specific operational needs, fostering innovation in design and application across various sectors. Overall, the benefits of marine copper casting significantly contribute to enhanced operational efficiency and cost-effectiveness in marine and industrial contexts.

Marine copper casting plays a pivotal role in various sectors, particularly in the marine and offshore industries. Due to its excellent corrosion resistance and high thermal and electrical conductivity, marine copper casting is widely utilized in the manufacturing of components such as ship propellers, heat exchangers, and electrical connectors. These components are essential for the performance and efficiency of marine vessels, ensuring longevity and reliability even in harsh seawater environments.

Moreover, marine copper casting extends its applications to the renewable energy sector, particularly in the construction of wind turbines and underwater energy generation systems. The superior strength and durability of copper alloys allow for the development of parts that can withstand extreme conditions while maintaining optimal performance. In the aquaculture industry, marine copper castings are also employed in the creation of cages and equipment that resist biofouling, significantly improving the sustainability of fish farming operations. Through these diverse applications, the benefits of marine copper casting continue to advance technology and efficiency across multiple sectors.

The marine copper casting process is integral for producing components that endure harsh marine environments. To optimize this process, several best practices should be implemented. First, ensuring the right alloy composition is crucial. Marine-grade copper alloys often incorporate elements like tin and nickel, enhancing corrosion resistance and strength, which are paramount in marine applications. According to a recent report by the Marine Engineering Institute, components produced with these alloys showcase a 30% longer lifespan compared to standard copper in seawater environments.

Another key practice involves temperature control during casting. Properly managing furnace temperatures minimizes defects such as porosity and promotes uniform solidification. Maintaining a consistent temperature range is essential, as fluctuations can lead to structural weaknesses in the cast. Experts recommend monitoring the melt temperature closely and using advanced thermocouples for precise readings.

**Tips:**

- Regularly maintain casting machinery to ensure optimal performance.

- Consider using simulation software to predict potential casting defects before actual production, significantly reducing waste and improving efficiency.

Lastly, post-casting processes like heat treatment and surface finishing should not be overlooked, as they further enhance the functionality and longevity of the copper components. Experts advocate for rigorous testing and inspection protocols to evaluate the integrity and quality of the final products, ensuring they meet industry standards.

| Aspect | Description | Advantages | Applications |

|---|---|---|---|

| Material Properties | Marine copper has excellent corrosion resistance, especially in saltwater. | Durability and longevity in harsh marine environments. | Boat fittings, marine hardware, and heat exchangers. |

| Casting Process | Involves melting copper and pouring it into molds under controlled conditions. | Allows for complex shapes and precision in dimensions. | Marine instrumentation and components. |

| Maintenance | Regular inspection and cleaning to prevent corrosion and fouling. | Extends the service life of marine components. | Yacht maintenance and repair operations. |

| Best Practices | Use high-quality raw materials and precise casting techniques. | Improved material properties and reduced defects in casting. | High-performance marine applications and custom parts. |

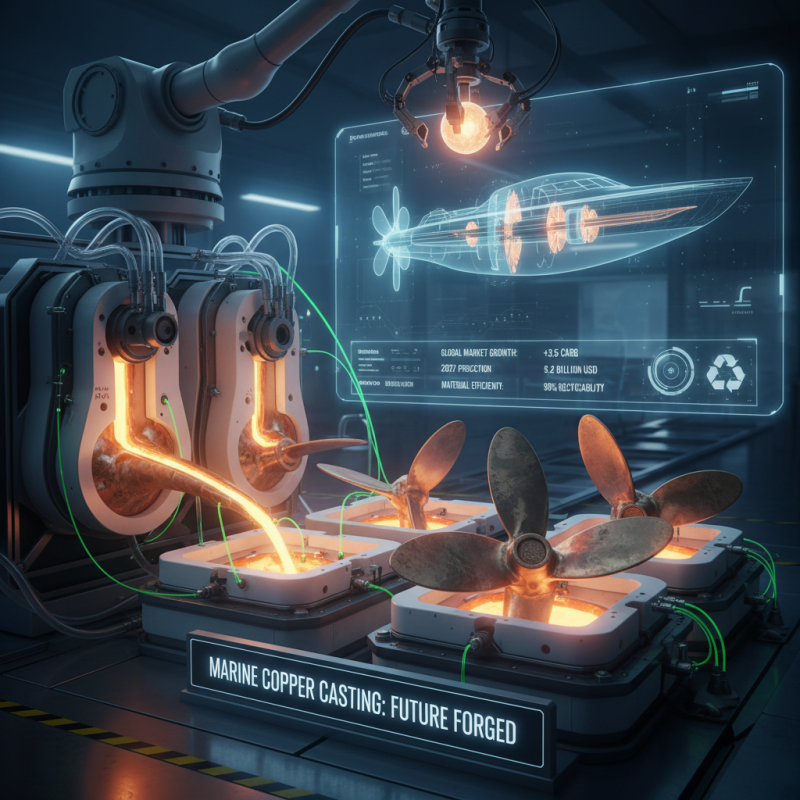

The future of marine copper casting technology is poised for significant advancements, driven by the increasing demand for high-performance materials in marine applications. Recent market research indicates that the global marine casting market is expected to grow significantly, projected to reach USD 4.2 billion by 2027, with a CAGR of over 3.5% from 2022 to 2027. This growth can be attributed to greater investments in marine infrastructure and the rising trend for sustainable and efficient marine vessels. As manufacturers look to incorporate more robust and corrosion-resistant materials, innovations in copper casting processes will likely emerge, enhancing the quality and durability of marine components.

Emerging trends include the integration of smart technologies in casting processes, such as advanced simulation software that allows for predictive modeling and optimization of casting designs. This enables engineers to refine their designs for better performance and lower production costs. Moreover, the push for eco-friendly practices in the marine industry is leading to advancements in recycling and reusing copper materials, further reducing the environmental impact of casting operations. A report from the International Copper Association suggests that recycled copper maintains its inherent qualities, thus positioning itself as a sustainable choice for future marine applications. Adopting such practices not only addresses global sustainability goals but also provides economic benefits for manufacturers looking to stay competitive in a rapidly evolving market.