As the manufacturing landscape continues to evolve, the importance of advanced techniques in the production process cannot be overstated. Copper Precision Casting has emerged as a pivotal innovation, offering unparalleled accuracy and efficiency in the manufacturing sector. According to a recent report by Smithers Pira, the global market for precision casting is expected to reach $10.67 billion by 2027, growing at a CAGR of 6.2% from 2022. This surge is largely driven by the increasing demand for high-performance materials in industries ranging from aerospace to electronics. The inherent properties of copper, such as its excellent thermal and electrical conductivity, combined with advancements in precision casting technologies, are revolutionizing the way manufacturers approach production challenges. In this context, exploring the latest innovations within Copper Precision Casting reveals significant opportunities for enhanced productivity and product quality, ultimately shaping the future of manufacturing.

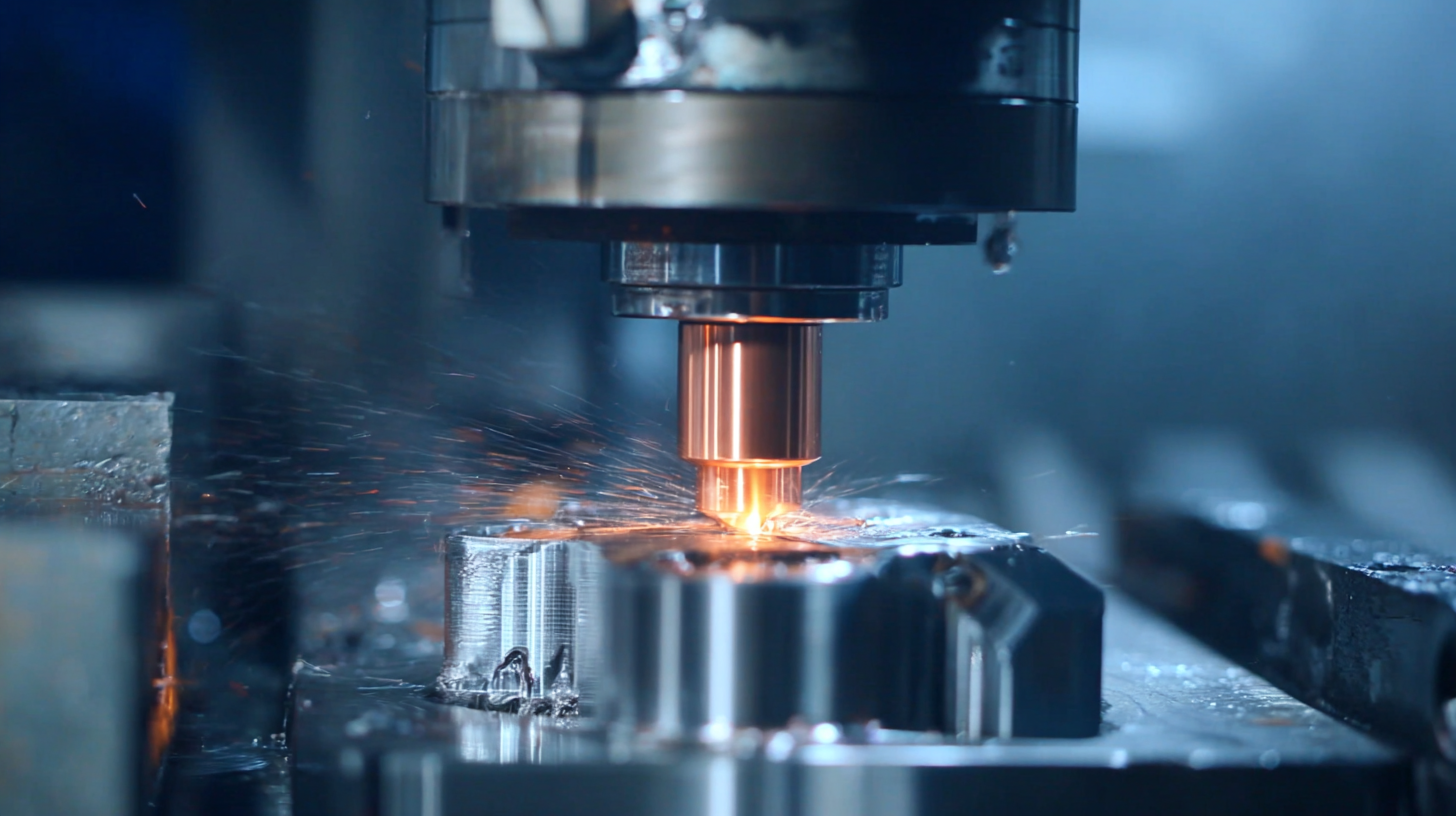

The future of copper precision casting is being shaped by several key technologies that are revolutionizing the manufacturing landscape. One significant advancement is the introduction of computer-aided design (CAD) software, which allows engineers to create highly detailed and complex designs that can be precisely translated into casting molds. This technology enhances the accuracy and quality of castings, reducing material waste and production costs.

Another pivotal innovation is the development of advanced alloys and composite materials. These new materials not only improve the mechanical properties of castings but also enhance their thermal and electrical conductivity. This is particularly important for applications in the electronics and automotive industries, where performance and reliability are crucial. Additionally, the integration of automation and robotics in the casting process increases efficiency and minimizes the likelihood of human error, further solidifying the promise of copper precision casting in modern manufacturing.

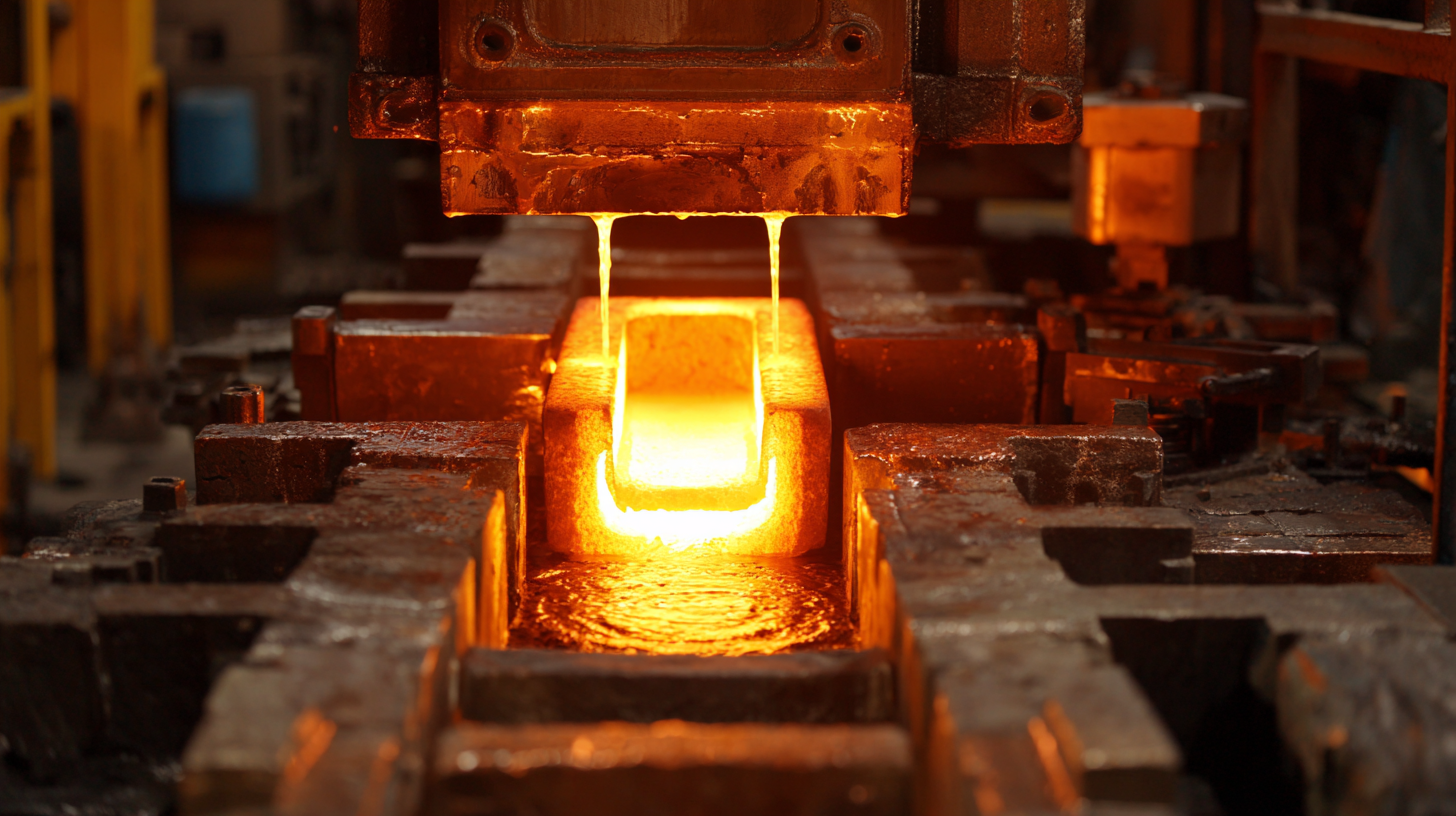

Advanced copper casting techniques are paving the way for more efficient manufacturing processes. With the integration of innovative short process technology, manufacturers are now able to achieve faster production times while maintaining high precision in their castings. This advancement not only reduces energy consumption but also minimizes waste, which is crucial for sustainable practices in the industry.

The ongoing research in nanotechnology further enhances the performance of copper alloys, allowing for the production of high-strength materials that meet the demands of modern applications. Additionally, revolutionary recovery technologies are transforming the extraction process, dramatically improving efficiency and overall output in copper mining. As the industry embraces these innovations, the potential for efficiency improvements and cost reductions continues to grow, shaping a more sustainable future for copper precision casting.

| Technique | Efficiency Improvement (%) | Applications | Benefits |

|---|---|---|---|

| Vacuum Casting | 25 | Aerospace, Electronics | Reduces defects, enhances strength |

| Investment Casting | 30 | Automotive, Machinery | High precision, complex geometries |

| Centrifugal Casting | 20 | Pipes, Tubes | Improved density, uniform wall thickness |

| Die Casting | 35 | Consumer Goods, Electronics | Fast production, good surface finish |

| 3D Printing with Copper | 40 | Prototyping, Custom Parts | Rapid prototyping, design flexibility |

The integration of smart manufacturing solutions in copper casting processes marks a significant shift in the way industries approach metal production. By utilizing advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), and machine learning, manufacturers can enhance precision and efficiency in copper casting. Smart sensors monitor parameters in real-time, allowing for immediate adjustments during the casting process, which minimizes defects and waste. These innovations not only improve product quality but also contribute to cost savings, making them essential in today’s competitive market.

Furthermore, the adoption of predictive analytics enables manufacturers to anticipate potential issues before they arise. By analyzing historical data and real-time performance metrics, smart manufacturing systems can predict equipment failures and optimize maintenance schedules. This proactive approach enhances operational reliability and reduces downtime, thereby streamlining the overall production process. As these smart solutions continue to evolve, the copper casting industry is poised for a revolution that promises greater sustainability, enhanced productivity, and the ability to meet the growing demands of various sectors, from electronics to construction.

The copper precision casting industry is undergoing a significant transformation as manufacturers increasingly adopt sustainable practices that not only reduce environmental impact but also enhance operational efficiency. According to a report by ResearchAndMarkets, the global copper casting market is projected to reach USD 113.8 billion by 2025, largely driven by the rising demand for eco-friendly products and processes. Innovative techniques such as green casting methods, which utilize recyclable materials and reduce energy consumption, are becoming commonplace. These advancements not only lower carbon footprints but also align with the growing consumer preference for sustainable manufacturing.

Moreover, incorporating waste reduction strategies and optimizing energy use can lead to substantial cost savings. A study from the International Copper Association highlights that companies adopting these sustainable practices can reduce energy usage by up to 30%, demonstrating a clear financial incentive alongside the environmental benefits. As manufacturers strive to meet stringent regulations and consumer demand for eco-responsibility, the future of copper precision casting is poised to be defined by these sustainable innovations, ultimately revolutionizing the manufacturing landscape.

Advancements in artificial intelligence (AI) and automation are transforming the landscape of copper precision casting, enhancing both quality and efficiency. By leveraging machine learning algorithms, manufacturers can analyze vast amounts of data from the casting process, identifying patterns that lead to defects. This capability allows for real-time adjustments to parameters such as temperature and pressure, significantly reducing the likelihood of faults and ensuring a smoother production flow.

Automation plays a crucial role in streamlining operations, minimizing manual intervention, and thus decreasing the risk of human error. Robotic systems equipped with advanced sensors and AI-driven decision-making capabilities can undertake repetitive and complex tasks with precision, ensuring consistent quality in copper castings. These innovations not only improve the structural integrity and surface finish of the castings but also enhance the overall productivity of manufacturing processes, setting a new standard for the industry.