When seeking the best Investment Casting Services, the process can often seem daunting given the myriad of options available in the market. Industry expert John Smith, a renowned figure in the field of metal casting, emphasizes, “Choosing the right investment casting provider is crucial for ensuring the quality and efficiency of your production.” This statement encapsulates the significance of making informed decisions in a sector where precision and expertise are paramount.

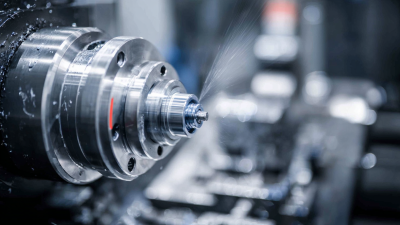

Investment casting, also known as lost-wax casting, is a cornerstone technique in manufacturing, allowing for the creation of intricate and precise components. The choice of a suitable service provider can significantly impact the outcome of a project, from the initial design phase through to the final product. With considerations ranging from material selection to technological capabilities, understanding the essential factors at play becomes imperative for achieving success in this highly specialized industry.

In this guide, we will explore ten essential tips that will help you navigate the selection process for Investment Casting Services, ensuring that your requirements are met while maintaining high standards of quality and performance.

When embarking on an investment casting project, understanding your specific requirements is crucial for selecting the right service provider. Investment casting is a highly precise manufacturing process that can produce intricate designs and complex geometries, making it a favored choice in industries such as aerospace and automotive. According to a report by Research and Markets, the global investment casting market was valued at approximately $15 billion in 2021 and is projected to grow significantly, highlighting its importance across various sectors.

Tip 1: Clearly define your project's specifications, including dimensions, tolerances, and material requirements. This foundation will help you communicate effectively with potential casting service providers, ensuring they understand your needs and can deliver the best solutions.

Additionally, it's important to consider the service provider's capabilities and technology. Many leading companies now utilize advanced software for modeling and simulation, enhancing the accuracy of the casting process. Tip 2: Check for certifications and industry standards compliance, as this indicates a commitment to quality and reliability in their casting services.

Lastly, don't overlook the significance of lead times and production flexibility. The ability to adapt to changes in project scope can be crucial for timely delivery. Tip 3: Discuss your project timelines upfront to gauge whether the casting service can meet your schedule without compromising on quality.

When researching investment casting service providers, it is vital to gather comprehensive information about potential candidates. Start by assessing their experience and expertise in your specific industry. Look for companies that have a proven track record in delivering high-quality parts and can demonstrate their success through case studies or client testimonials. Ensure they understand the unique challenges related to your project, as this knowledge can significantly impact the final results.

Next, comparing various providers is essential to find the most suitable fit. Request quotes from multiple companies and analyze their pricing structures alongside the services offered. Pay close attention to their manufacturing capabilities, turnaround times, and customer service. It is also beneficial to evaluate their quality assurance processes, as this will provide insight into their commitment to excellence. Engaging in conversations with their representatives can help gauge their responsiveness and willingness to accommodate your needs, ultimately leading to a more informed decision.

When selecting investment casting services, evaluating the quality assurance measures they employ is crucial for ensuring the final product meets your specifications and industry standards. High-quality investment casting services should implement a comprehensive quality control process that begins with the selection of raw materials. This includes thorough testing of metals and alloys to confirm they meet the required specifications, thereby minimizing defects in the final castings. Regular inspections during the casting process, coupled with stringent adherence to industry certifications, provide an additional layer of confidence in the service provider's commitment to quality.

Moreover, effective communication about quality assurance protocols is essential. A reputable investment casting service will be transparent about their practices, showcasing their ability to adapt to specific project requirements. They should offer detailed documentation of their quality checks at various stages, including pattern making, molding, and finishing. By understanding their quality assurance measures, you can better assess their capability to deliver precise and durable castings that align with your project's needs. Investing time in this evaluation will ultimately result in a more successful and satisfactory partnership.

| Quality Assurance Measure | Importance Rating (1-5) | Description | Inclusion in Service |

|---|---|---|---|

| Material Certification | 5 | Ensures materials meet specified standards to enhance durability. | Yes |

| Process Control | 4 | Involves monitoring the casting process to maintain quality. | Yes |

| Inspection and Testing | 5 | Conducts thorough inspections and tests to avoid defects. | Yes |

| Employee Training | 4 | Ensures staff are skilled in handling equipment and processes. | Yes |

| Traceability | 4 | Allows tracking of production for accountability. | Yes |

| ISO Certification | 5 | Indicates compliance with international quality standards. | Yes |

| Customer Feedback | 3 | Reviews from previous clients can provide insights into quality. | Yes |

| Technical Support | 3 | Access to knowledgeable support for issues and queries. | Yes |

| On-time Delivery | 5 | Timeliness in delivery matters for project schedules. | Yes |

| Flexibility in Production | 4 | Ability to adapt to changing requirements and designs. | Yes |

When selecting investment casting services, assessing the technological capabilities of the casting facilities is crucial for ensuring quality and efficiency.

According to a recent report by MarketsandMarkets, the investment casting market is projected to reach USD 20.32 billion by 2026, highlighting the increasing demand for technologically advanced casting solutions.

Facilities equipped with state-of-the-art technologies such as computer-aided design (CAD), computer-aided manufacturing (CAM), and 3D printing can significantly improve precision and reduce lead times, which are essential factors in competitive industries like aerospace and automotive.

Moreover, the integration of automation and robotics in casting processes can enhance quality control and production consistency.

A study by Research and Markets indicates that the automated metal casting industry is expected to witness considerable growth, driven by advancements in robotics and IoT.

Therefore, when evaluating investment casting services, it is vital to inquire about the specific technologies a facility utilizes, its capabilities in terms of material versatility, and how these innovations translate into measurable benefits, such as reduced scrap rates and shorter cycle times, ultimately contributing to cost savings and improved product performance.

When selecting the best investment casting services, reviewing customer testimonials and case studies can provide deep insights into a company's reliability and service quality. Testimonials from previous clients highlight their satisfaction with the craftsmanship, delivery timelines, and overall customer service. A company that consistently receives positive feedback demonstrates a commitment to meeting its clients’ needs, ensuring that you can expect a similar standard for your own projects.

Case studies further enhance this evaluation by showcasing real-world applications of the service. They illustrate how the investment casting service has resolved challenges for other clients, detailing the processes and outcomes. This not only reflects the technical capabilities of the company but also its ability to adapt and innovate in various scenarios. By analyzing these detailed narratives, potential customers can assess whether the service provider aligns with their specific requirements and industry standards, ultimately leading to informed decision-making.

This bar chart represents the customer satisfaction ratings for various dimensions in investment casting services, based on aggregated testimonials and case studies. The dimensions evaluated include Quality, Timeliness, Communication, and Overall Experience.