In today’s competitive manufacturing landscape, ensuring superior product quality is paramount for success. One effective method to achieve this is through the implementation of Precision Metal Casting techniques. These advanced casting processes not only enhance the dimensional accuracy and surface finish of the metal components but also allow for the production of intricate designs that traditional methods may struggle to accommodate.

By focusing on precision, manufacturers can reduce material waste and minimize the need for extensive post-processing, ultimately leading to cost savings and improved turnaround times. This article delves into various Precision Metal Casting techniques that can elevate product quality, ensuring that companies remain at the forefront of manufacturing excellence.

Understanding and applying these techniques will empower businesses to meet increasingly stringent quality standards and customer expectations in an evolving market.

Precision metal casting is a fundamental process that significantly contributes to product quality in various industries, including automotive, aerospace, and consumer goods. This technique allows manufacturers to create complex shapes and intricate designs with tight tolerances, ultimately enhancing the functionality and durability of the final products. According to a recent industry report by Mordor Intelligence, the global precision casting market is projected to grow at a CAGR of 7.5% from 2021 to 2026, highlighting its increasing importance in manufacturing processes.

One effective way to enhance product quality through precision metal casting is to focus on the selection of high-quality materials. Opting for alloys specifically designed for casting can improve strength and resistance to wear and corrosion. Additionally, maintaining precise temperature controls during the melting and pouring stages ensures a uniform distribution of material properties, which is crucial for the reliability of the end product.

Tips for Enhancing Quality:

- Conduct regular maintenance assessments on casting equipment to prevent defects.

- Invest in modern casting technologies, such as vacuum casting or investment casting, to achieve superior surface finishes and dimensional accuracy.

- Collaborate with suppliers and industry experts to continuously refine casting processes and material choices. By implementing these strategies, manufacturers can leverage precision metal casting to achieve exceptional product quality that meets evolving market demands.

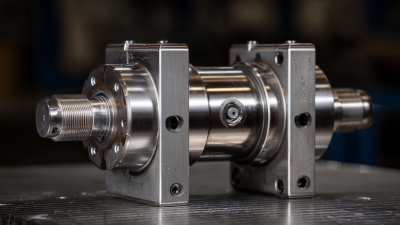

Precision metal casting techniques play a crucial role in enhancing product performance by ensuring that components are manufactured to exact specifications. One of the key techniques involves the use of investment casting, which provides superior surface finish and dimensional accuracy. This method is particularly beneficial for complex shapes, allowing designers to create intricate details without compromising on quality. Additionally, using high-quality molds can significantly reduce defects, leading to improved durability and functionality of the final product.

Tips: Always conduct thorough material research to choose alloys that best suit the application, as the right material can drastically improve wear resistance and overall performance. It's also essential to maintain strict control over the casting temperature to prevent unwanted inclusions and porosity, which can weaken the final product.

Another effective technique is sand casting, which is highly versatile and cost-effective. By using different types of sand mixtures, manufacturers can tailor properties like strength and permeability, enhancing the casting process. Furthermore, adopting modern technologies such as 3D printing for pattern making can lead to more efficient production cycles and reduced lead times, ultimately boosting product quality while staying competitive in the market.

Tips: Implementing regular quality checks throughout the casting process can catch potential issues early, ensuring higher reliability and performance in the finished products.

Precision metal casting is integral to enhancing product quality, yet several challenges must be addressed to optimize its efficacy. Common issues include dimensional accuracy, surface finish, and defects such as porosity and shrinkage. To combat these challenges, companies like Hitchiner Manufacturing have embraced automated blue light 3D scanning technology. By integrating advanced measurement procedures, they can improve internal inspection processes, ensuring that cast components meet stringent quality standards.

Tips for overcoming casting challenges include investing in cutting-edge technologies such as 3D scanning and optimizing alloy combinations to reduce the risk of defects. Additionally, prioritizing employee training can enhance skill levels, ensuring that workers are adept at handling complex casting processes.

The global metal casting market is expected to grow from USD 220.49 billion in 2024 to USD 235.41 billion by 2025, highlighting the need for companies to innovate continuously. By focusing on precision and utilizing modern techniques such as die casting and 3D printing, organizations can not only address existing challenges but also stay competitive in an ever-evolving industry landscape.

Precision metal casting techniques have been successfully implemented across various industries to improve product quality and meet specific design requirements. For instance, in the aerospace sector, companies utilize precision casting to produce lightweight, complex components with minimal tolerances. A case study of a leading aircraft manufacturer demonstrates how this technique enabled the creation of intricate engine parts that not only reduced weight but also enhanced fuel efficiency. This application showcases the ability of precision casting to fulfill the rigorous standards of safety and performance in high-stakes environments.

Another compelling example can be found in the medical device industry, where precision metal casting plays a crucial role in fabricating surgical instruments and implants. A renowned medical equipment firm adopted precision casting to develop custom orthopedic implants tailored to individual patient anatomies. This not only improved the fit and function of the implants but also significantly shortened recovery times for patients. The case highlights how precision casting can cater to specific industry demands, ultimately leading to advancements in functionality and patient outcomes.

| Industry | Application | Precision Technique Used | Quality Improvement (% Increase) | Key Benefits |

|---|---|---|---|---|

| Automotive | Engine Components | Investment Casting | 15% | Weight Reduction, Increased Strength |

| Aerospace | Structural Parts | Die Casting | 20% | Improved Durability, Cost Efficiency |

| Medical Devices | Surgical Tools | Sand Casting | 10% | Precision Tolerance, Biocompatibility |

| Electronics | Housing Components | Low Pressure Casting | 18% | Enhanced Heat Dissipation, Aesthetic Finish |

| Heavy Machinery | Gear Systems | Centrifugal Casting | 12% | Increased Load Capacity, Longevity |

As we delve into the future trends in precision metal casting, it becomes evident that advancements in technology will play a pivotal role in enhancing product quality. According to a report by MarketsandMarkets, the global precision casting market is projected to reach $38.3 billion by 2026, growing at a compound annual growth rate (CAGR) of 7.3%. This growth is largely driven by the increasing demand for lightweight, high-strength materials in industries such as automotive and aerospace, where stringent quality standards are paramount.

The integration of digital technologies such="float: none;"> as Artificial Intelligence (AI) and the Internet of Things (IoT) is set to revolutionize precision metal casting processes. These technologies facilitate real-time monitoring and predictive maintenance, significantly reducing defects and improving overall product quality. A study from the American Foundry Society highlights that incorporating advanced data analytics could lead to a reduction in scrap rates by up to 25%, allowing manufacturers to meet tighter tolerances while minimizing material waste.

As businesses embrace these innovations, we can expect a substantial rise in quality standards, fostering greater competitiveness in the precision metal casting sector.