Choosing the right electrical copper castings for your project is crucial to ensuring optimal performance and durability in electrical applications. Copper's exceptional conductivity and resistance to corrosion make it a favored material in a variety of industrial settings. However, with numerous options available on the market, selecting the appropriate type and specification of electrical copper castings can be overwhelming. This blog aims to guide you through the essential factors to consider, including the intended application, casting methods, and design requirements. Whether you are working on a large-scale industrial project or a smaller, specialized application, understanding these key elements will empower you to make informed decisions, ultimately leading to successful project outcomes. Join us as we delve into the important considerations and expert tips for choosing the right electrical copper castings tailored to your specific needs.

When selecting the right electrical copper castings for your project, it’s crucial to understand the various types available in the market. The most common types of copper castings include sand castings, investment castings, and die castings. Sand castings are often favored for their ability to create complex shapes and provide a low-cost option for large parts. They are versatile but may require additional finishing work to achieve the desired surface quality.

On the other hand, investment castings allow for higher precision and a smoother finish, making them ideal for intricate designs in high-performance applications. This method is particularly beneficial when the dimensional accuracy and surface finish are of paramount importance. Finally, die castings are a great choice for mass production scenarios where speed and repeatability are essential. Each type offers distinct advantages depending on the specific requirements of your project, such as volume, complexity, and cost considerations, making it imperative to assess these factors prior to making a decision.

When selecting electrical copper castings for your project, several key factors come into play that can significantly impact the performance and overall success of your application. One crucial aspect to consider is the purity of the copper used in the casting. According to the Copper Development Association, high-purity copper (99.9% or greater) is vital for maintaining excellent electrical conductivity, which can range up to 100% in well-manufactured components. This purity level ensures minimal resistive losses and enhances the efficiency of your electrical systems.

Another important factor is the casting method employed, as it directly affects the mechanical properties and reliability of the final product. Die casting and sand casting are two prevalent methods, each offering unique advantages. For instance, die casting allows for intricate designs with tight tolerances, while sand casting is ideal for larger, more complex components. According to a report from MarketsandMarkets, the global die casting market is projected to reach USD 55.15 billion by 2026, reflecting a growing demand for precision components across various industries.

Tips: When choosing copper castings, always verify supplier certifications to ensure compliance with industry standards. Additionally, consider the environmental factors your castings will face, such as exposure to moisture or corrosive elements, which can affect durability. Aim for castings that incorporate protective coatings to enhance longevity and performance in challenging environments.

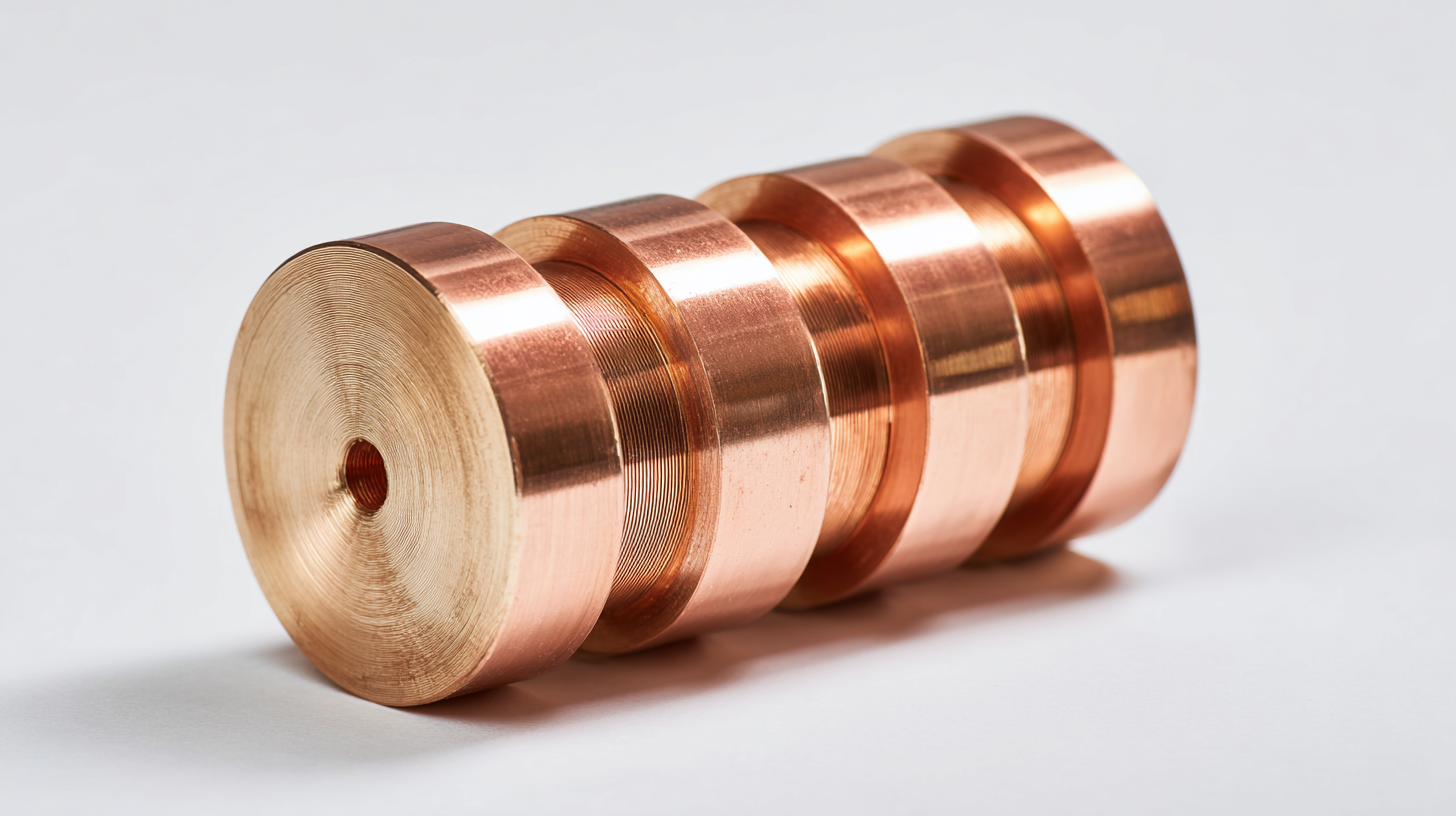

When selecting the right electrical copper castings for your project, understanding the different types available is essential. Each type of copper casting offers unique advantages that can significantly impact your project's performance and efficiency. For instance, centrifugal castings are known for their excellent mechanical properties and corrosion resistance, making them ideal for high-stress applications. According to a report by Grand View Research, the demand for centrifugal copper castings in electrical applications is projected to grow by over 5% annually through 2026, driven by the increasing use of renewable energy technologies.

Another popular option is die-casting, which allows for precision manufacturing with complex geometries. This method minimizes waste and enhances the material's structural integrity, which is critical in electrical applications where conductivity and durability are paramount. A study by MarketsandMarkets highlights that the global die-casting market is expected to reach $102.4 billion by 2025, reflecting a surge in applications across various sectors, including electric vehicles and consumer electronics. Understanding these advantages will help you choose the right copper casting that aligns with your project's specific requirements, ensuring optimal performance and longevity.

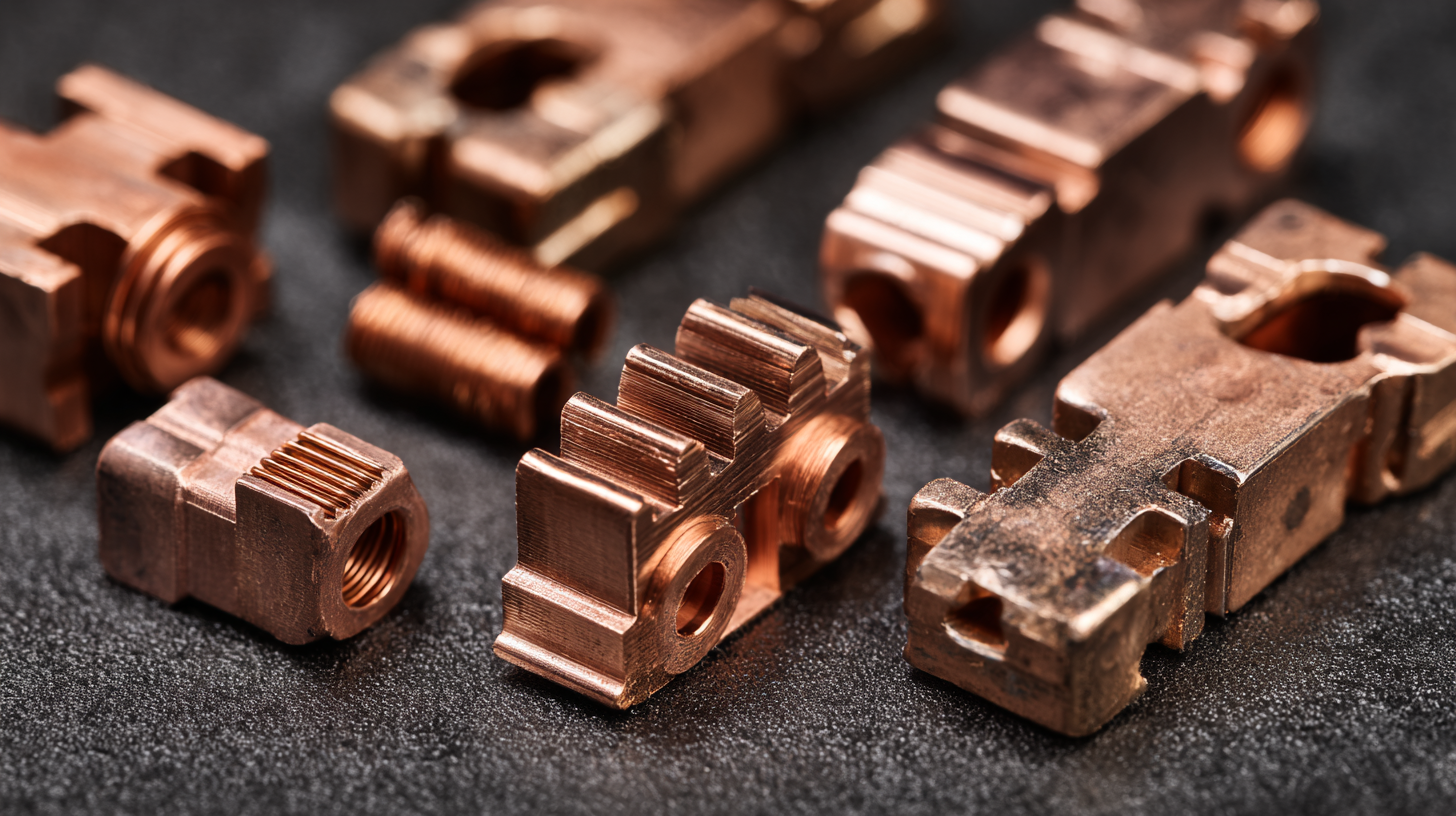

When it comes to electrical copper castings, it's essential to match the right type to your project needs. Different applications call for various types of copper castings, each with unique properties and benefits. For instance, high-conductivity copper castings are ideal for electrical connectors and components that require efficient conductivity. These castings ensure minimal energy loss and maximal performance in electrical systems.

Another common application is in the manufacturing of electric motors and generators. In this case, you might opt for copper alloys that provide enhanced strength and durability under high operational demands. When selecting castings for these applications, consider the operational environment and mechanical stress to ensure longevity.

Tips for choosing the right casting include assessing the thermal and electrical conductivity required for your project. Additionally, always evaluate the casting's compatibility with other materials, as this can significantly affect performance and longevity. Finally, don’t hesitate to consult with manufacturers or suppliers who can guide you in selecting the best casting for your specific use case, ensuring optimal performance in your electrical applications.

When selecting electrical copper castings for your project, maintaining quality and performance is paramount. According to a recent industry report from the Copper Development Association, the conductivity of copper castings can vary significantly based on the manufacturing processes used. The report highlights that high-quality castings can achieve conductivity ratings of up to 100% IACS (International Annealed Copper Standard), which is crucial for maximizing energy efficiency in electrical applications. Understanding these performance metrics ensures that you choose copper castings that meet your project's specifications.

Moreover, the durability and resistance to corrosion in electrical copper castings are essential for long-term performance. A study conducted by the National Institute of Standards and Technology demonstrates that well-maintained copper castings can exhibit lifespan enhancements of up to 50% when compared to lower-quality alternatives. This longevity not only reduces replacement costs but also minimizes downtime in production, making it vital to consider both quality and performance indicators when making your selection. Prioritizing these aspects will undoubtedly lead to a more successful outcome in your electrical projects.

This chart illustrates the quality scores of different electrical copper casting types based on factors such as conductivity, durability, and thermal performance. The data represents a hypothetical analysis of common casting types used in electrical applications.