In the rapidly evolving landscape of manufacturing, Precision Investment Casting has emerged as a pivotal process that enables industries to produce intricate components with unparalleled accuracy and efficiency. As we look ahead to 2025, optimizing this technique is paramount for businesses aiming to reduce waste and enhance productivity. According to a report by Allied Market Research, the global precision casting market is projected to reach $34.2 billion by 2027, underscoring the increasing demand for precise and reliable casting methods across diverse sectors, including aerospace, automotive, and medical industries.

Experts in the field, such as Dr. Emily Chen, a renowned specialist in casting technologies, emphasize the importance of refinement in this process. She asserts, "The future of manufacturing lies in harnessing the full potential of Precision Investment Casting, where innovation can lead to significant efficiencies and cost savings." This sentiment highlights the necessity for companies to adopt best practices and the latest advancements in technology to stay competitive. By focusing on key optimization strategies, organizations can not only meet but exceed industry standards, setting the stage for sustainable growth and enhanced operational performance in the coming years.

Precision investment casting, also known as lost-wax casting, is a manufacturing process that allows for the production of intricate components with high dimensional accuracy. This method is particularly valued across various industries, including aerospace, automotive, and medical devices due to its ability to create complex geometries that traditional machining methods may struggle to achieve.

According to a report by MarketsandMarkets, the global precision investment casting market is projected to reach USD 22.88 billion by 2025, growing at a CAGR of 5.8% from 2020. This growth underscores the rising demand for lightweight and durable components in end-use industries.

In terms of applications, precision investment casting is ideal for creating parts that require both precision and a reduced weight. Aerospace components, such as turbine blades, benefit from the process as it allows for the optimization of the airfoil shape, enhancing performance while minimizing weight. Additionally, medical equipment, such as surgical instruments, requires precise specifications and surface finishes, making precision casting an excellent choice.

Data from the American Foundry Society indicates that precision investment casting can achieve tolerances as tight as ±0.005 inches, further demonstrating its suitability for high-purity and detailed parts across sectors.

In the realm of investment casting, several key factors drive efficiency and precision in production processes. One of the most significant aspects is the temperature control during melting and pouring. Studies indicate that maintaining a stable temperature can improve the quality of the cast and reduce defect rates by up to 30%. Variations in temperature can lead to inclusions or improper solidification, adversely affecting the material properties of the final product.

Another crucial factor is mold design and material selection. Advanced simulation tools and software have enabled manufacturers to optimize mold design, which in turn enhances the flow of molten metal and minimizes thermal stress. Reports from industry analysts suggest that utilizing high-quality, thermal-resilient materials for molds can increase production efficiency by as much as 25%, as it allows for quicker turnaround times and extended mold life. Additionally, incorporating features such as gating systems that facilitate optimal metal flow can drastically reduce cycle times, making the process both faster and more cost-effective.

Furthermore, workforce training and technology integration play vital roles in maximizing efficiency. A well-trained workforce familiar with modern machinery and best practices can significantly enhance the precision of the investment casting process. According to a survey conducted by the Investment Casting Institute, companies that invest in continuous training report a 15% increase in overall productivity. Coupled with the adoption of automation and real-time monitoring systems, firms can achieve higher quality outputs and reduce material waste, contributing to a more sustainable production approach.

| Key Factor | Description | Impact on Efficiency (%) | Optimization Techniques |

|---|---|---|---|

| Material Selection | Choosing the right alloy can reduce waste and improve the quality of castings. | 20 | Perform material property tests. |

| Casting Process Design | An optimized mold design minimizes defects and improves fluidity. | 30 | Employ simulation software for mold flow analysis. |

| Temperature Control | Maintaining optimal temperatures during melting and pouring can reduce defects. | 15 | Use precise thermal monitoring systems. |

| Quality Control Practices | Regular inspections and non-destructive testing ensure quality standards. | 10 | Implement a robust quality management system. |

| Machining and Finishing | Post-processing can improve surface quality and dimensional accuracy. | 25 | Utilize advanced CNC machining technologies. |

In the realm of investment casting, material selection is critical for achieving optimal performance. The choice of materials not only influences the mechanical properties of the final product but also impacts the overall efficiency of the casting process. For instance, utilizing high-quality alloys can enhance strength and durability while reducing the likelihood of defects during casting.

It's essential to consider the thermal properties of these materials since certain alloys can better withstand the temperature fluctuations during the casting process, leading to improved dimensional accuracy.

Tips: When evaluating material options, prioritize alloys that have proven track records in your specific application. Additionally, conducting thorough research into the material’s compatibility with your casting technique will help prevent common issues such as warping or cracking.

Furthermore, the incorporation of modern advanced materials, such as titanium or nickel-based superalloys, can elevate the performance of investment castings in demanding environments. These materials often provide superior resistance to corrosion and can handle extreme temperatures, making them ideal for industries such as aerospace and energy.

Tips: Always consult with material scientists or industry experts when selecting materials, as their insights can guide you towards achieving not only the best performance but also cost-effectiveness in your investment casting projects.

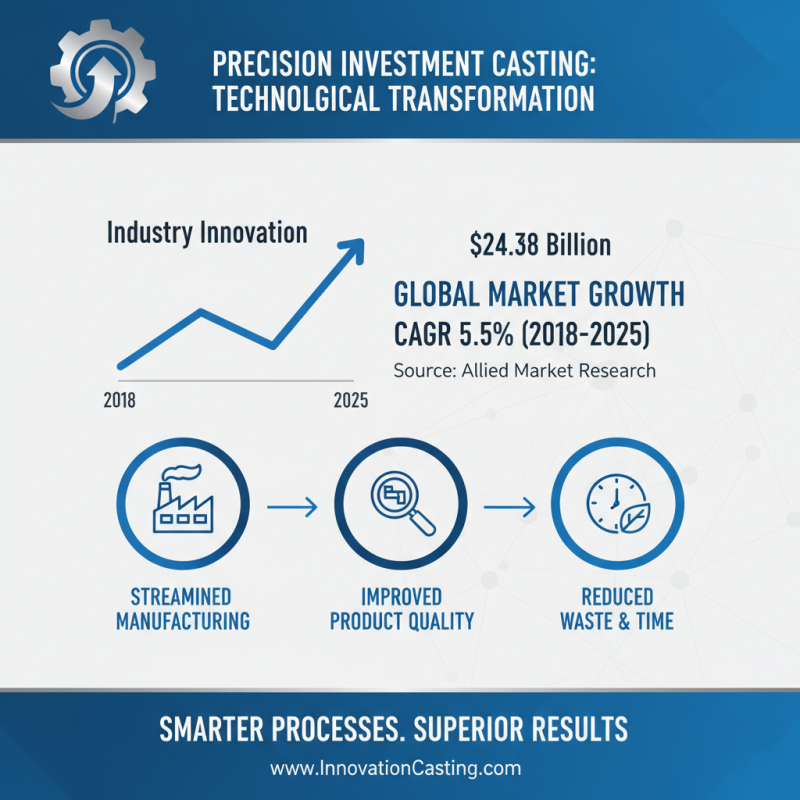

In recent years, the precision investment casting industry has witnessed transformative technological innovations that significantly enhance efficiency. According to a market analysis by Allied Market Research, the global investment casting market is projected to reach $24.38 billion by 2025, with a compounded annual growth rate (CAGR) of 5.5% from 2018. These advancements not only streamline manufacturing processes but also improve the quality of the cast products, reducing waste and minimizing production time.

One of the pivotal innovations reshaping the industry is the adoption of automated and smart manufacturing technologies, which integrate Artificial Intelligence (AI) and the Internet of Things (IoT). A report by McKinsey estimates that AI implementation across manufacturing processes could lead to a productivity increase of up to 20%. Additionally, these technologies enable real-time monitoring and adjustments during the casting process, thereby enhancing precision and reducing the risk of defects. Furthermore, advancements in materials science, such as the development of new alloys and coatings, allow for better thermal stability and enhanced performance of cast products, aligning with the rising demand for high-performance components in industries such as aerospace and automotive.

The integration of simulation software has also played a crucial role in improving casting design and efficiency. By utilizing techniques like Computational Fluid Dynamics (CFD) and Finite Element Analysis (FEA), manufacturers can predict potential issues and optimize the casting process before production begins. This proactive approach reduces lead times and ensures the production of components that meet the increasingly stringent quality standards in today’s competitive market. Collectively, these technological advancements not only enhance the efficiency of precision investment casting but also position the industry for sustained growth and innovation in the coming years.

Quality control is paramount in investment casting to ensure that the final products meet the desired specifications and performance standards. Implementing robust quality control measures can significantly enhance yield and minimize defects. Throughout the production process, techniques such as dimensional inspections, surface finish evaluations, and metallurgical analysis can identify potential issues early on. By utilizing advanced technologies like 3D scanning and non-destructive testing methods, manufacturers can detect discrepancies that may arise during the casting, thereby allowing for corrective actions before the final stages of production.

Another crucial aspect of quality control in investment casting is the establishment of standardized procedures and documentation. Consistent monitoring of variables such as temperature, pressure, and mold materials can lead to more reliable outcomes. By maintaining comprehensive records of each production batch, manufacturers can trace defects back to their sources, leading to continuous improvement in processes and techniques. Regular training for personnel on quality standards and techniques ensures that everyone involved in the process is aware of the importance of maintaining high quality, ultimately fostering a culture of excellence that contributes significantly to maximizing yield.